HDWA-SVX001D-EN

31

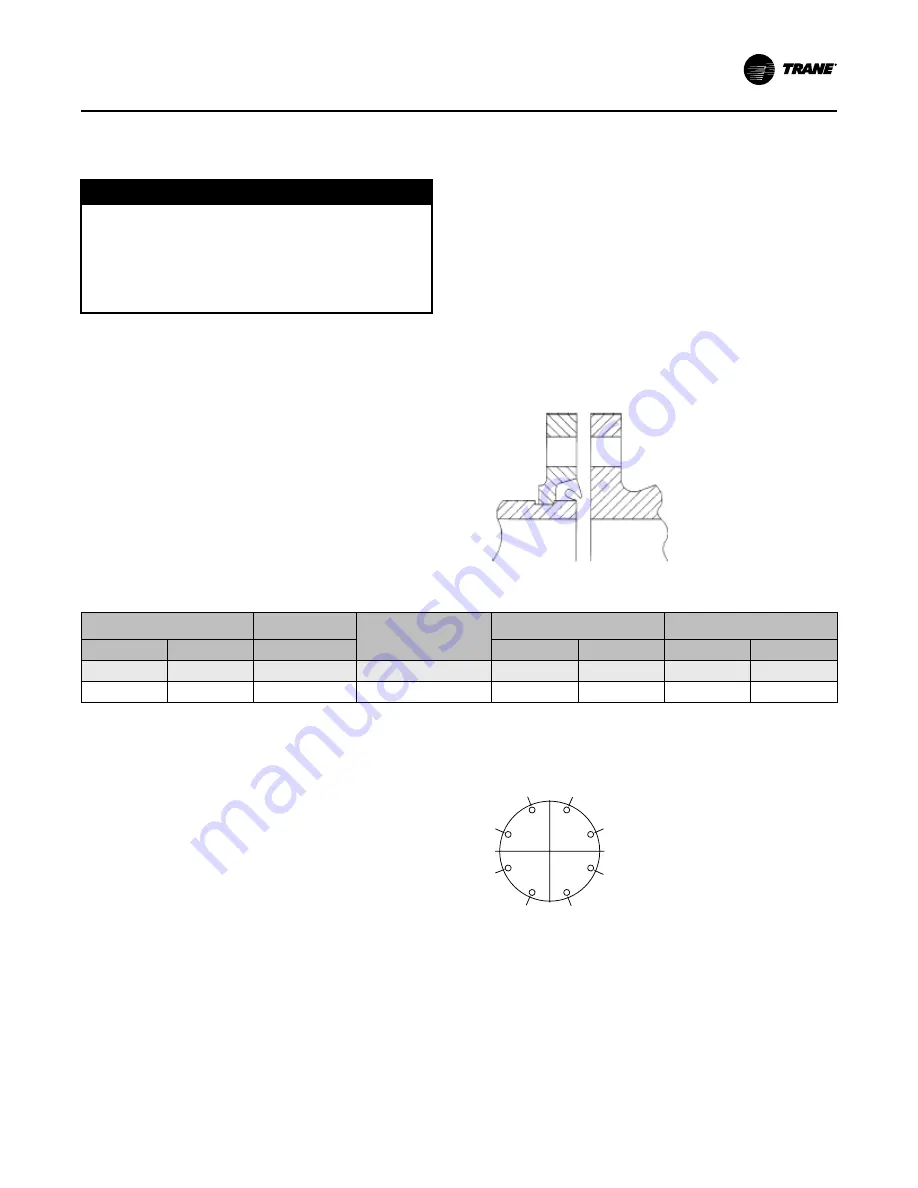

The flange-adapter gasket must be placed with the

color-coded lip on the pipe and the other lip facing the

mating flange.

N

NO

OT

TIIC

CE

E

P

Piip

piin

ng

g C

Co

on

nn

ne

eccttiio

on

n L

Le

ea

akkss!!

F

Fa

aiillu

urre

e tto

o p

prro

ov

viid

de

e e

effffe

eccttiiv

ve

e sse

ea

all cco

ou

ulld

d rre

essu

ulltt iin

n

e

eq

qu

uiip

pm

me

en

ntt o

orr p

prro

op

pe

errtty

y--o

on

nlly

y d

da

am

ma

ag

ge

e..

T

To

o p

prro

ov

viid

de

e e

effffe

eccttiiv

ve

e sse

ea

all,, g

ga

asskke

ett cco

on

ntta

acctt ssu

urrffa

acce

ess

o

off a

ad

da

ap

ptte

err m

mu

usstt b

be

e ffrre

ee

e o

off g

go

ou

ug

ge

ess,, u

un

nd

du

ulla

attiio

on

nss o

orr

d

de

effo

orrm

miittiie

ess..

Victaulic Gasket Installation

1. Inspect supplied gasket to be certain it is suited for

intended service (code identifies gasket grade).

Apply a thin coat of silicone lubricant to gasket tips

and outside of gasket.

2. Install gasket, placing gasket over pipe end and

making sure gasket lip does not overhang pipe end.

Refer to the following figure for gasket

configuration.

3. Align and bring two pipe ends together and slide

gasket into position centered between the grooves

on each pipe. No portion of the gasket should

extend into the groove on either pipe.

4. Open fully and place hinged Victaulic

®

flange

around the grooved pipe end with the circular key

section locating into the groove.

5. Insert a standard hex head screw through the

mating holes of the Victaulic

®

flange to secure the

flange firmly in the groove.

6. Tighten fasteners alternately and equally until

housing screw pads are firmly together (metal-to-

metal); refer to

“Screw-Tightening Sequence for

Water Piping Connections,” p. 31

. Do NOT

excessively tighten fasteners.

N

No

otte

e:: Uneven tightening may cause the gasket to

pinch.

Figure 20.

Typical Victaulic

®

®

flange gasket

configuration

Table 10.

Installation data for 150 psig (1034.2 kPaG) flange adapters (Style 741)

Nominal Pipe Size

Assembly

Screw Size

(a)

Number of Assembly

Screws Required

Screw Pattern Diameter

Weight

in.

mm

in.

in.

mm

lb

kg

6

168.3

3/4 x 3-1/2

8

9.5

241

10.3

4.7

8

219.1

3/4 x 3-1/2

8

11.75

298

16.6

7.5

(a)

Screw size for conventional flange-to-flange connection. Longer screws are required when flange washer must be used. Grade 5 screws are

recommended.

Screw-Tightening Sequence for

Water Piping Connections

This section describes a screw-tightening sequence for

flanges with flat gaskets or O-rings. Remember that

improperly tightened flanges may leak.

N

No

otte

e:: Before tightening any of the screws, align the

flanges.

Flanges with 8 Screws

Tighten all screws to a snug tightness, following the

numerical sequence for the appropriate pattern as

shown in the following figure. Repeat this sequence to

apply the final torque to each screw.

Figure 21.

Flange screw tightening sequence (8

screws)

1

3

4

5

7

8

2

6

8 screws