17

ST1-075A Ia 12/98

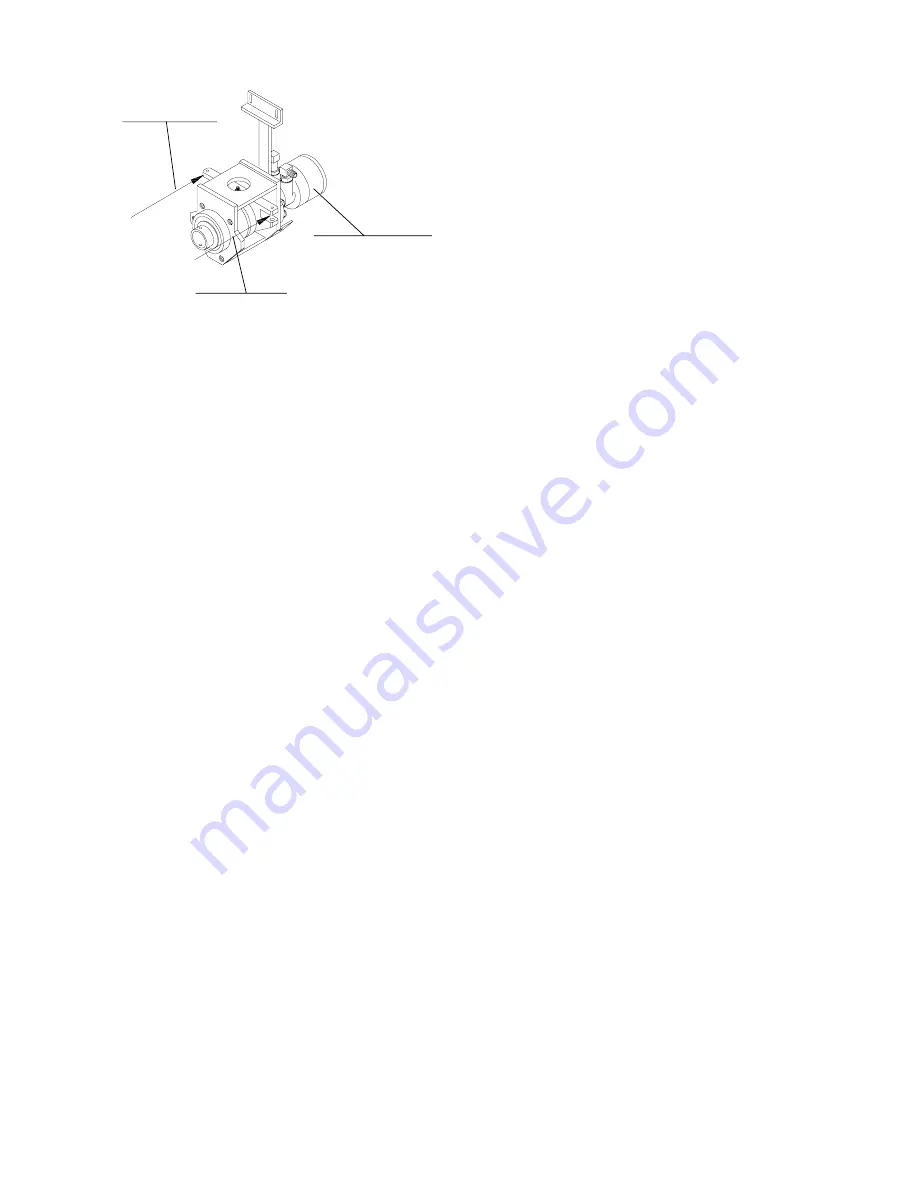

Figure 18

Drive Module Disassembly (Figure 19)

1.

Place drive module assembly in vice.

2.

Check shaker bearing assembly for end play

(Figure 19) before disassembling the drive

module assembly. Shaker bearing end play

can best be checked using the following

procedures.

•

Place dial indicator near center of shaker

drive plate (Figure 18).

•

While using back and forth hand force

against ends of shaker drive plate read dial

indicator.

NOTE: If dial indicator reading is more than .010

inch, bearing assembly should be disassembled

and bearings replaced with bearing kit. Refer to

drive module reassembly if old shaker bearings are

reused.

3.

Remove bolt (item 1) & grease fitting (item 11).

4.

Remove four bolts (item 10).

5.

Pull motor from assembly.

6.

With blunt one inch brass drift remove the

coupling block (item 3). The bearing (item 4)

and seal (item 2) will remain in the housing.

7.

Remove shaker bearing assembly from the

housing.

8.

Remove bearing and seal from housing (items

2 & 4).

9.

Remove push-pull joints by removing locking

bolts (item 13) & then drive out pins (item 12).

10. Remove shaker bearings (item 17) by

removing the lock nut (item 15), lock washer

(item 14) and nylos ring (item 16). A four inch

spanner wrench is required to remove lock nut

(item 15).

11. Inspect all components before

reassembly.

12. Motor seal kits are available with

disassembly/assembly instructions.

Drive Module Reassembly (Figure 19)

Reassemble in reverse order as noted in the

disassembly instructions. Care must be taken

regarding the following items.

1.

When old shaker bearings are reused surface

grind the spacer ring (item 9) equal to the end

play plus .002 inch determined at disassembly

(see step 2 in disassembly) e.g. for .005 inch

end play plus .002 for preload remove .007

inch from spacer with surface grinder. New

bearing sets are supplied with a new spacer

ring as a kit.

2.

Torque the lock nut (item 15) to 100-150 lb/ft.

Sockets are available for use with a torque

wrench. An adjustable spanner wrench with an

extension applying the force required relative

to wrench and extension length may also be

used, eg force (125 lbs) x length (1 ft) = 125 lb/

ft.

3.

Torque bolt (item 1) to 100 lb/ft.

4.

Torque six socket head capscrews (item 20) to

100 lb/ft.

5.

After torquing six socket head capscrews,

install shim stacks which were removed (item

21).

NOTE: Shim stack must fill complete space

between modular housing and frame to within .010

inch before tightening through bolts and nuts (item

22 & 26) to 40 lb-ft.

6.

The flow control valve is normally set at

adjustment point 6 for proper operating sped

(Figure 14, item 7).

7.

Auger speed of 240 to 260 rpm must be

checked with sandbagger on host vehicle.

Higher number on flow control increases speed

and lower number reduces speed.

OM0210

Shaking Direction

Set dial indicator in this

area to check shaker

bearing end play

Shaking Direction