INDEX

CAUTION

Install saw blade and blade guard

before use. Set proper blade tension

Pag.

1.0 INTRODUCTION TO USE...............................

2

1.1 SYMBOLS PLACED IN

CORRESPONDANCE WITH USAGE

POINTS .......................................................2

to prevent any danger caused by

damaged saw blade or work piece.

1.2 SAFETY AND RULES ..................................2

1.3 RECOMMENDED AND NOT

RECMMENDED USAGE.............................3

1.0 INTRODUCTION TO USE

1.4 STANDARD SAFETY PROCEDURS...........3

1.5 SAFETY PROCEDURS FOR FURTHER

RISKS ..........................................................3

Before starting work with your sawing machine, carefully

read this instructions manual so that you are familiar with

the machine and its uses and where it should not be used.

Keep this manual in a safe place.

1.6 NOISE CONDITION .....................................3

1.7 INFORMATION ABOUT THE

ELECTROMAGNETIC COMPTIBILITY ......3

It is an integral part of the machine and should be used for

reference in operating the machine correctly and in the

proper safety conditions.

1.8 DESCRIPTION OF THE MACHINE .............3

2.0 INSTALLATION ...............................................

3

2.1 REMOVING THE PACKAGING ...................3

Use the machine only and exclusively for the uses

specified below, as recommended in this manual. The

machine should not in any way be tampered with, or

forced, or used for unsuitable purposes.

2.2 HANDLING ...................................................4

2.3 TRANSPORTATION.....................................4

2.4 POSITION/WORK STATION........................4

2.5 ELECTRICAL CONNECTION ......................4

3.0 ADJUSTMENT.................................................

4

1.1 SYMBOLS PLACED IN CORRESPONDANCE

3.1 TENSION OF THE BLADE...........................4

WITH USAGE POINTS

3.2 BAR STOP....................................................4

Never underestimate the warnings “ ATTENTION –

CAUTION ” given in this manual.

3.3 CUTTING ANGLE.........................................4

3.4 CUTTING SPEED.........................................4

In order to draw the user’s attention and to preserve safety,

hazardous operation are preceded by symbols and notes

that point out the danger and explain how to behave to

avoid any risk.

3.5 SLIDING BLADE GUIDE ..............................4

3.6 BEARINGS BLADE GUIDE ..........................5

4.0 USE ..................................................................

5

4.1 RUNNING-IN THE BLADE ...........................5

These symbols and notes are divided in three categories,

identified by the following words:

4.2 WORKING ....................................................5

4.3 REPLACING THE BLADE ............................5

4.4 CUTTING CAPACITY...................................6

Attention:

dangerous-behaviours that could cause serious

injuries.

4.5 POSITIONING OF THE PIECE IN THE

CLAMP ........................................................6

4.6 CUTTING TABLE .........................................6

CAUTION:

behaviours that could cause slight injuries or

damages to things.

5.0 ACCESSORIES ...............................................

6

5.1 CHOISING THE BLADE ...............................6

6.0MAINTENANCE................................................

6

NOTE:

the notes preceded by this symbols are technical

and are aimed at making operations easier.

6.1 REGULAR MAINTENANCE .........................6

6.2 ASSISTENCE ...............................................6

6.3 DISPOSAL OF THE MACHINE....................7

1.2 SAFETY AND RULES

7.0 TROUBLESHOOTING.....................................

7

The machine was designed and built according to the

Community Directives in force: EEC 98/37 –EEC

91/368 – EEC 93/68 – EEC 73/23 – EEC 89/336.

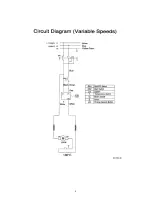

CIRCUIT DIAGRAM ...........................................8

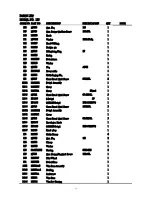

PARTS LISTS…………………………………….10

The enclosed CE declaration of conformity, togheter

with the CE mark on product, essentially comprise and are

an integral part of the machine : both guarantee product

conformity with the aforesaid safety Directives.

2