Trouble-shooting and diagnostic facilities

©

TR-Electronic GmbH 1997, All Rights Reserved

Printed in the Federal Republic of Germany

Page 44 of 45

TR - ECE - BA - GB - 0009 - 08

03/04/2010

According to the PNO encoder profile, an encoder must set the bits 'Ext.diag'

(extended diagnostic information available) and 'Stat.diag' (static error) in the

event of an internal error being detected in the station status. This means that,

in case of error, the encoder stops providing position data and is removed from

the process image by the PROFIBUS master until the error bits are reset. It is

not possible for the user to acknowledge the error via the PROFIBUS in this

way.

This function is only guaranteed provided the Commissioning Diagnostic

function is activated.

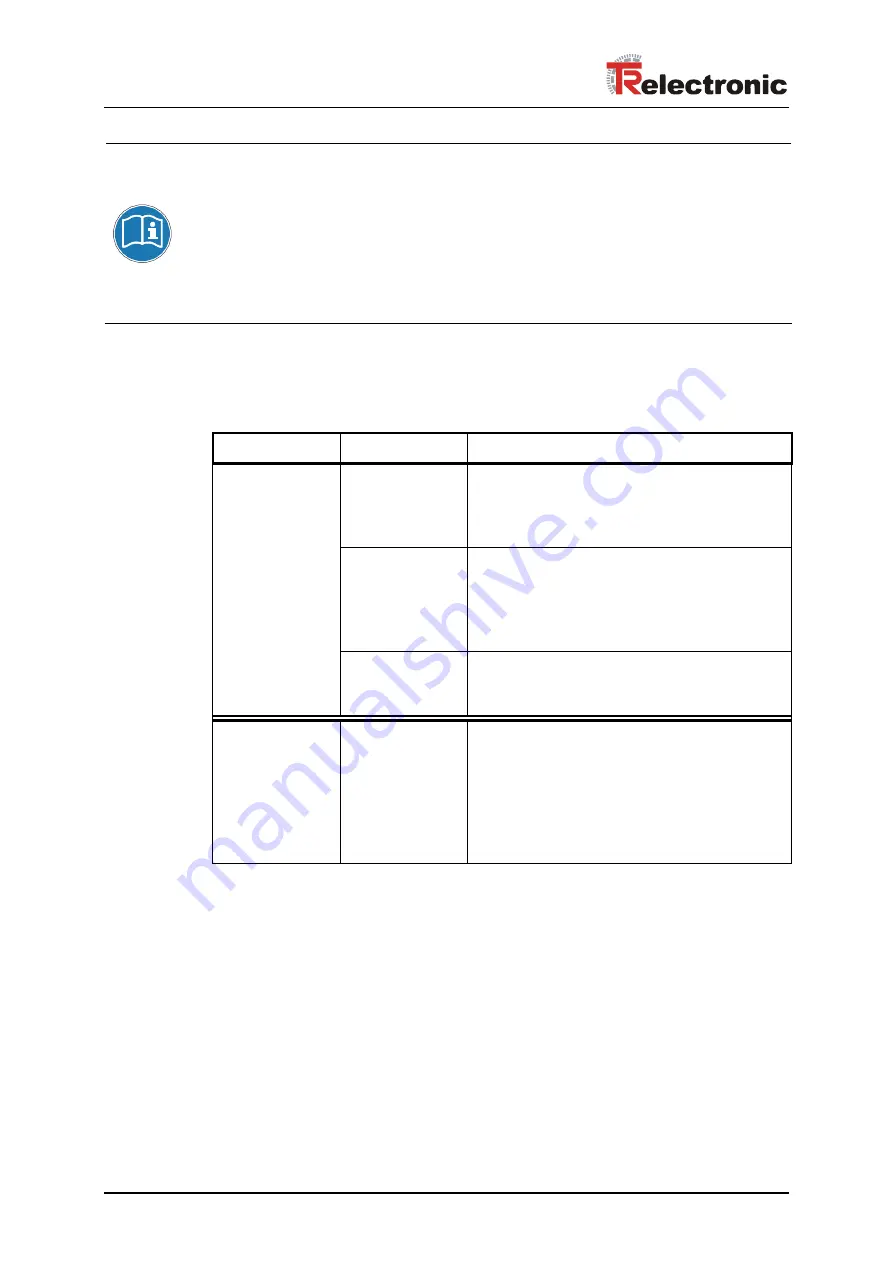

4.3 Other faults

Fault Cause

Remedy

Encoder step

changes

Strong vibrations

Vibrations, shocks and jolts, e.g. on presses, are

cushioned by so-called "shock modules". If the error

persists despite these precautions, the encoder must be

replaced.

Electrical

faults

EMC

Electrical faults can be countered by means of insulating

plastic flanges and couplings, and by data and power

supply cables with twisted-pair conductors. The screening

and wiring arrangement must conform to the assembly

guidelines for PROFIBUS.

Excessive axial and

radial loading of shaft

or scanning defect.

Couplings prevent mechanical strain on the shaft. If the

error persists despite this precaution, the encoder must be

replaced..

Profibus operates

when the encoder is

not connected, but

indicates a fault when

the bus cover is

mounted on the

encoder

PROFIBUS Data-A

and Data-B reversed

Inspect all connections and conductors relating to the

wiring of the encoder.