EC03O--01

EC3069

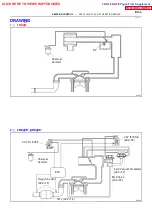

Check Valve (Vacuum Valve)

Gasket

A01265

A01266

Compressed Air

A01263

Compressed Air

--

EMISSION CONTROL

EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

EC--5

EVAPORAT IVE EMI SSION (EVAP)

CONTROL SYSTEM

INSPECTION

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loosen connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK

Look for deformation, cracks or fuel leakage.

3. VISUALLY INSPECT FUEL TANK CAP

Check if the cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

4. 1RZ -- FE:, 2RZ -- FE:, 3RZ -- FE:

RE MO V E CHARCO AL CANI S T E R

5. 2RZ -- FE:, 3RZ -- FE:

REMOVE VSV

6. VISUALLY INSPECT CHARCO AL CANI S T E R

Look for cracks or damage.

7. CHECK FOR CLOGGED FILTER, AND STUCK

CHE CK VALV E AND DI AP HRAG M

(a)

Using low pressure compressed air (6.66 kPa, 68 gf/cm

2

,

0.97 psi), blow into tank pipe and check that air flows with-

out resistance from the other pipes.

(b)

Blow air (6.66 kPa, 68 gf/cm

2

, 0.97 psi) into purge pipe

and check that air does not flow from the tank pipe and air

flows without resistance from the other pipe.

If a problem is found, replace the charcoal canister.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE