10

OPERA

TIONS

MM491G

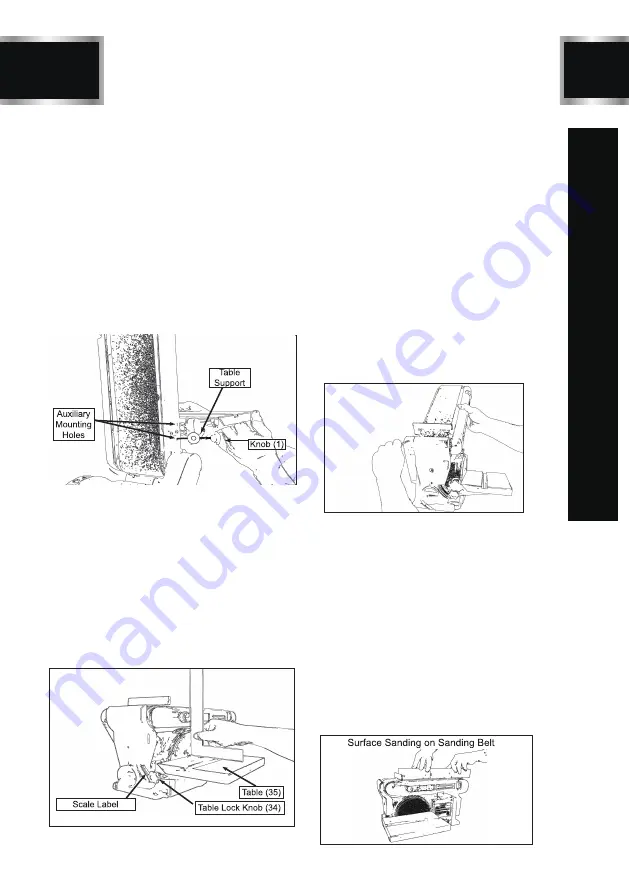

Remounting Table for

Vertical Sanding

1. Remove backstop lock bolt and remove work

support.

2. Unscrew knob (34) and remove.

3. Pull table support (33) index pin out of mo-

unting hole.

4. Loosen hex socket screw (75) and raise

sanding bed to the desired sanding position.

5. Insert the table index pins into the auxiliary

(upper) holes in the sanding bed.

6. Tighten hex socket screw (75). Make sure

table is not touching sanding belt.

Leveling Table Assembly

1. Place a combination square on the table (35)

so that it also touches the sanding pad (7).

See below. If the table is 90 degrees to the

pad, the square is flush on the pad.

2. If the table is not 90 degrees to the with the

pad, loosen the table lock knob (34) and tilt

the table until the square is flush with the pad

.

3. Retighten the knob to secure the table.

4. Attach the scale label to the ‘0’ degrees mark

on the dust guard.

Installing and Adjusting the

Sanding Belt

1. Turn power switch to the OFF position and

disconnect power cord from the main elec

tricity supply.

2. Move tension lever (66) to the right to rel-

ease the sanding belt tension (10).

3. Place the sanding belt over the drive and

idler drums (13 and 65), making sure that

the inside direction arrow points down,

towards the drive drum (13) as shown in

illustration..

4. Centre belt on both drums.

5. Slide tension lever (66) to the left to tighten

belt tension.

6. Tighten hex. socket screw (56) when bed

(4) is in desired working position.

7. Reconnect the power cord to the main

electricity supply. Turn the no-volt release

switch (21) ON, then OFF, while viewing

the belt movement. If the belt looks like it

was going to slide off either drum, the belt

tracking needs to be adjusted (described

in the next step).

8. If the sanding belt (87) moves towards

the sanding pad (7) when turned ON, turn

the tracking knob (55) clockwise ¼ turn,

and test again.

9. If the sanding belt moves away from the

sanding pad when it was turned ON, turn

the tracking knob counterclockwise ¼ turn,

and test again.

Summary of Contents for MM491G

Page 2: ......

Page 12: ...BD4603 11 MM491G OPERATIONS...

Page 15: ...14 EXPLODED VIEW MM491G...

Page 20: ......