5

Drain piping

Following the Installation Manual, perform the drain piping work so that water is properly drained.

Apply a heat insulation so as not to cause a dew condensation.

Inappropriate piping work may result in water leakage in the room and wet furniture.

• Provide the indoor drain piping with proper heat insulation.

• Provide the area where the pipe connects to the indoor unit with proper heat insulation. Improper heat insulation

will cause condensation to form.

• The drain pipe must be sloping downward (at an angle of 1/100 or more), and do not run the pipe up and down

(arched shape) or allow it to form traps. Doing so may cause abnormal sounds.

• Restrict the length of the traversing drain pipe to 65'7" (20 m) or less. For a long pipe, provide support

brackets at intervals of 4'9" (1.5 m) to 6'6" (2 m) to prevent flapping.

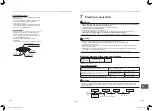

• Install the collective piping as shown in the following figure.

• Do not provide any air vents. Otherwise, the drain water will spout, causing water to leak.

• Do not allow any force to be applied to the connection area with the drain pipe.

• A hard PVC pipe cannot be connected to the drain pipe connecting port of the indoor unit. Be absolutely sure to

use the flexible hose provided for the connections with the drain pipe connecting port.

• Adhesive agents cannot be used for the drain pipe connecting port (hard socket) of the indoor unit. Be absolutely

sure to secure the pipe using the hose bands provided. Use of an adhesive agent may damage the drain pipe

connecting port or cause water to leak.

CAUTION

Drain pipe

connecting port

(hard socket)

Attached

hose band

Adhesive

agent

prohibited

Soft

socket

Soft

socket

VP 20 Polyvinyl

chloride pipe

(locally procured)

Attached drain hose

4'9" (1.5 m) to 6'6" (2 m)

Drain pan

Downward slope

1/100 or more

As long as possible

(Approx. 3.9" (10 cm))

Downward slope

1/100 or more

VP30

Incorrect

Trap

Arched shape

Support

bracket

(Collective

piping)

Heat

insulator

Attached hose band

Pipe material, size and insulator

Connection of drain hose

Connecting drain pipe

Drain up

Heat insulating process

The following materials for piping work and insulating process are procured locally.

• Insert the attached drain hose into the drain pipe connecting port on the drain pan up to the end.

• Fit the attached hose band to the end of the pipe connecting port, and then tighten it securely.

Connect the hard vinyl chloride pipe (locally procured) to the mounted drain hose which

was attached. When Plug is detached, the drain pipe is not damaged. It causes the water

leak.

In case of taking pipe from the left side

In case of taking pipe from the left side, exchange the plug from left to right.

Push in the plug of which end is not sharp up to the end.

• Fix the drain hose with the attached hose band, and set the

tightening position upward.

• As the draining is the natural water draining, arrange the pipe

outside of the unit on the down slope.

• If piping is performed as shown in the figure, drain cannot be

discharged.

When a down-gradient cannot be secured for the drain pipe, drain-up piping is possible.

• The height of the drain pipe must be 23.6" (600 mm) or less from the underside of the indoor unit.

• When Drain Pump Kit (sold separately) is installed, drain pipe and refrigerant pipe can only be connected from

upper direction.

• Using the attached drain hose heat insulator, lap the connecting section and the drain hose without clearance,

and then tighten with two handing band so that heat insulator does not open.

• Covering the attached drain hose heat insulator, lap the heat insulator (locally procured) to the drain pipe without

clearance.

REQUIREMENT

NO GOOD

Drain pipe

Drain pan

0.4" (10 mm)

to 0.6" (15 mm)

0.4" (10 mm)

to 0.6" (15 mm)

Drain pan

Confirm that soft hose is pushed in up to the end of the drain pan.

Attached drain hose

Drain pipe

Drain pipe Plug

Refrigerant pipe

Fit the attached hose band to the end of the

hose, lay down the knob, and then tighten hose

band.

* Fasten the binding bands in such a manner as to not

squeeze the attached insulating material excessively.

* Tighten the banding band so that attached

heat insulator is not pushed excessively.

Lap covering connecting section

between drain pan and drain hose. Heat insulator

(locally procured)

Hose band

Drain hose

Banding band

Attached heat insulator

Hose band

Drain

pan

Lap the attached

heat insulation so

that the one end is

put on the other end

at the upper side.

Fit the attached hose band to the end

of the hose, with both of the two knobs

oriented sideways.

Pipe material

Hard vinyl chloride pipe VP20 (Nominal outer diameter 1.1" (26 mm))

Insulator

Foamed polyethylene foam, thickness: 0.4" (10 mm) or more

� 12 �

23-EN

24-EN

EN

1115652713-1_EN,FR,ES.indd 13

25/3/2565 15:46:24