3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

After turning the power off there might still be a potential

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

Do not use pliers to loosen or tighten the Anode Cap

terminal, this may cause the spring to be damaged.

*

*

REMOVAL

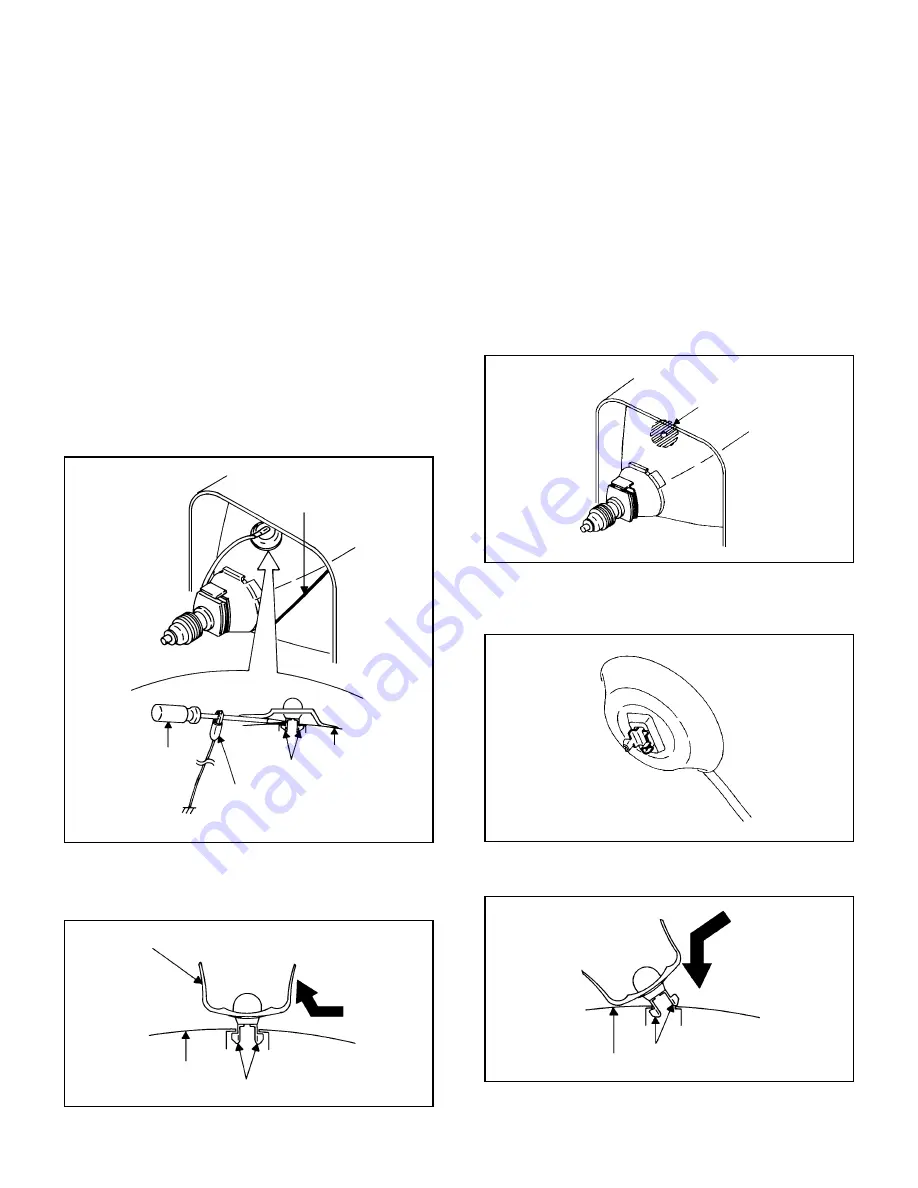

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 3-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

Flip up the sides of the Rubber Cap in the direction of the

arrow and remove one side of the support.

(Refer to Fig. 3-2.)

2.

GND on the CRT

Screwdriver

Alligator Clip

Support

CRT

GND on the CRT

Rubber Cap

CRT

Support

Fig. 3-1

Fig. 3-2

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

DISASSEMBLY INSTRUCTIONS

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 3-3.)

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

2.

3.

Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Fig. 3-4

4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 3-5.

CRT

Support

Fig. 3-5

5.

6.

Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

Location of Anode Cap

Fig. 3-3

Take care not to damage the Rubber Cap.

B3-1