MJ-1103/1104

© 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

ADJUSTMENTS

5 - 12

5.4

Saddle Stitch Skew Adjustment

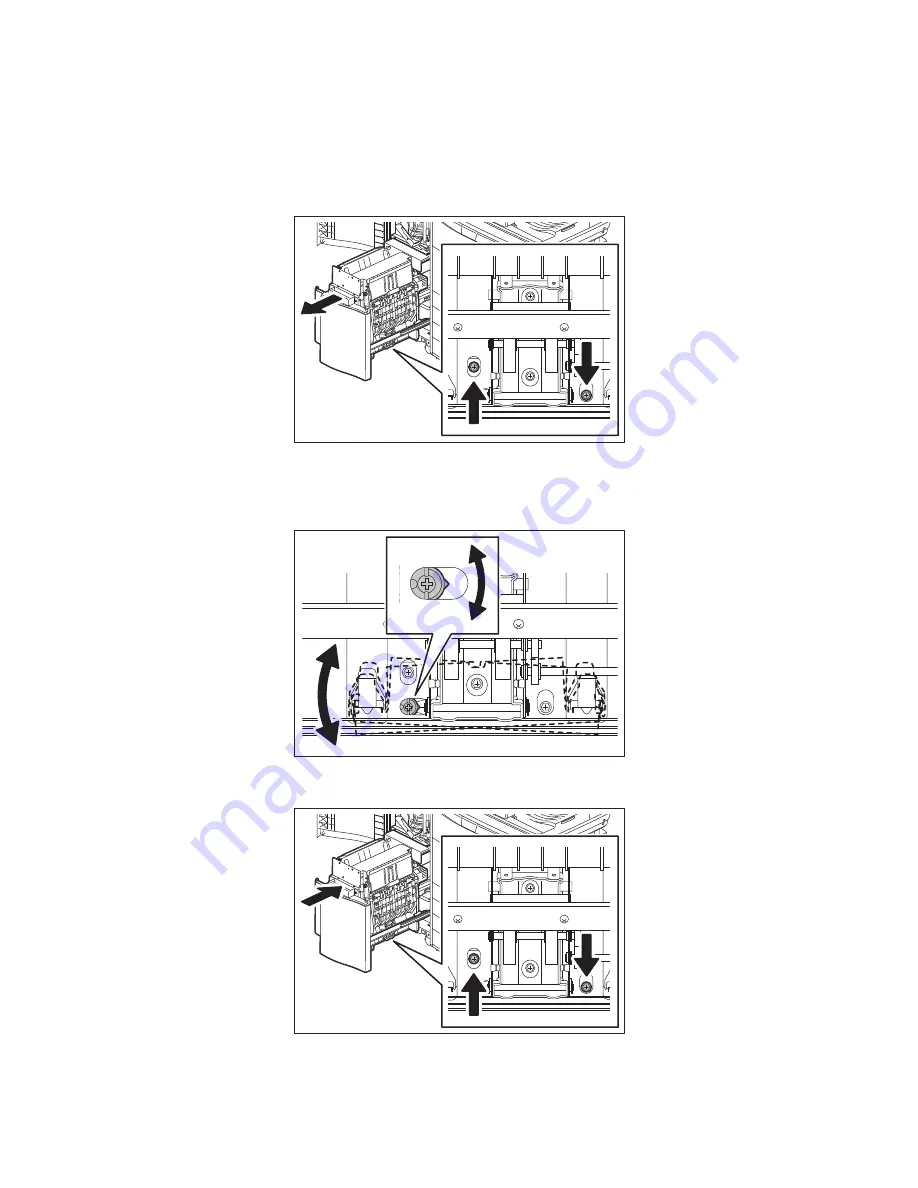

Perform this adjustment when the folding position for saddle stitching is tilted.

(1) Turn OFF the power of the equipment.

(2) Open the cover, pull out the saddle stitch section, and then loosen the 2 screws.

Fig. 5-16

(3) Rotate the adjustment screw slightly.

(4) Tighten the 2 screws, return the saddle stitch section, and then close the cover.

Summary of Contents for MJ-1103

Page 28: ...MJ 1103 1104 2008 2009 TOSHIBA TEC CORPORATION All rights reserved GENERAL DESCRIPTION 2 16 ...

Page 277: ... C Saddle control PC board Fig 8 34 ...

Page 278: ...MJ 1103 1104 2008 2009 TOSHIBA TEC CORPORATION All rights reserved ELECTRIC CIRCUIT 8 34 ...

Page 280: ...MJ 1103 1104 2008 2009 TOSHIBA TEC CORPORATION All rights reserved REVISION RECORD 2 ...

Page 281: ......

Page 282: ......