6

Specifications

Toshiba

B

‐

FV4T

Owner’s

Manual

‐

53

‐

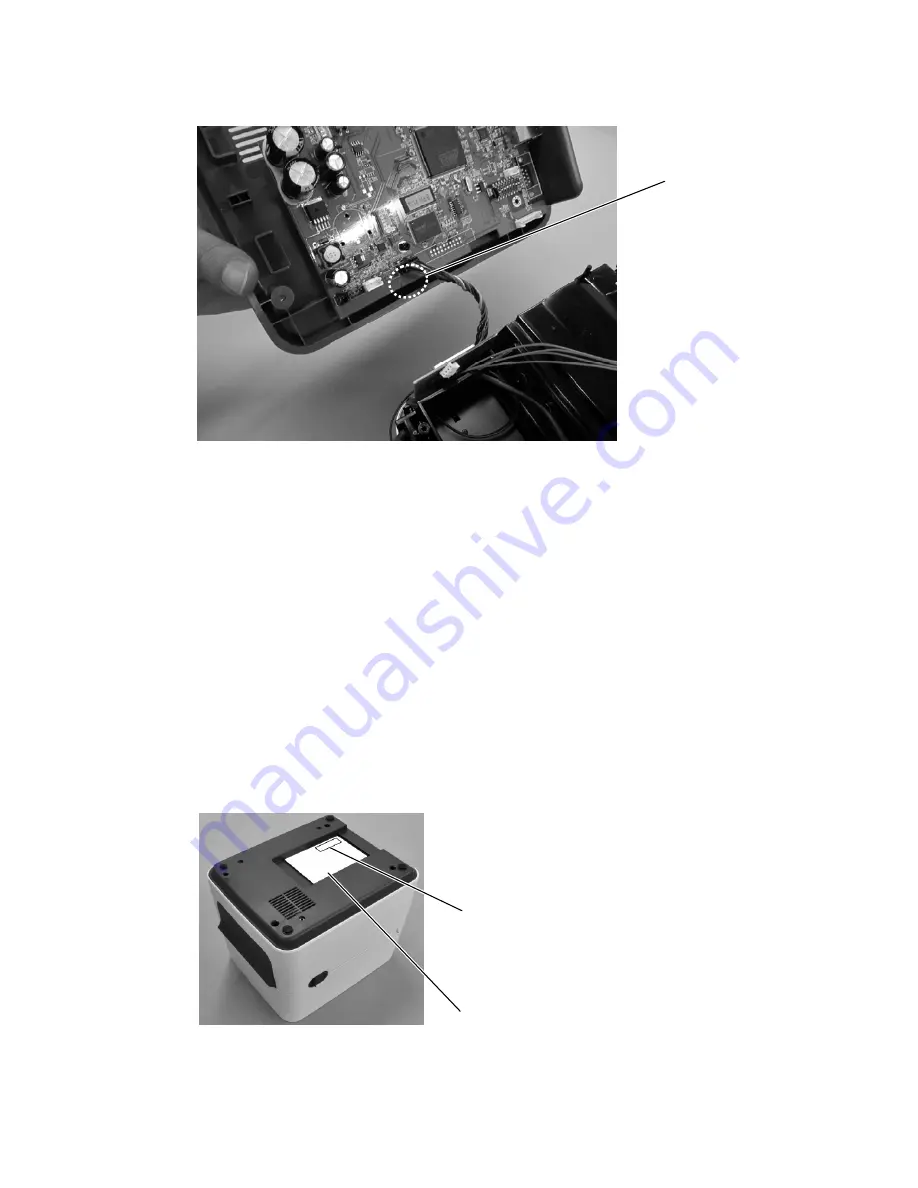

7) Connect the harness connector to the connector “J15” (black) on the main board.

8) Return the 6 connectors to the original positions, which were removed in Step 3.

9) Fix the Bottom Cover by securing the 4 screws which were removed in Step 2.

Note: When fitting the Bottom Cover, prevent the harness from being trapped between the

covers.

10) Peel off the backing sheet of the RF Certification Label and attach it to the position as

shown below.

Connector

“J15”

(black)

RF

Certification

Label

Rating

Label