E-7

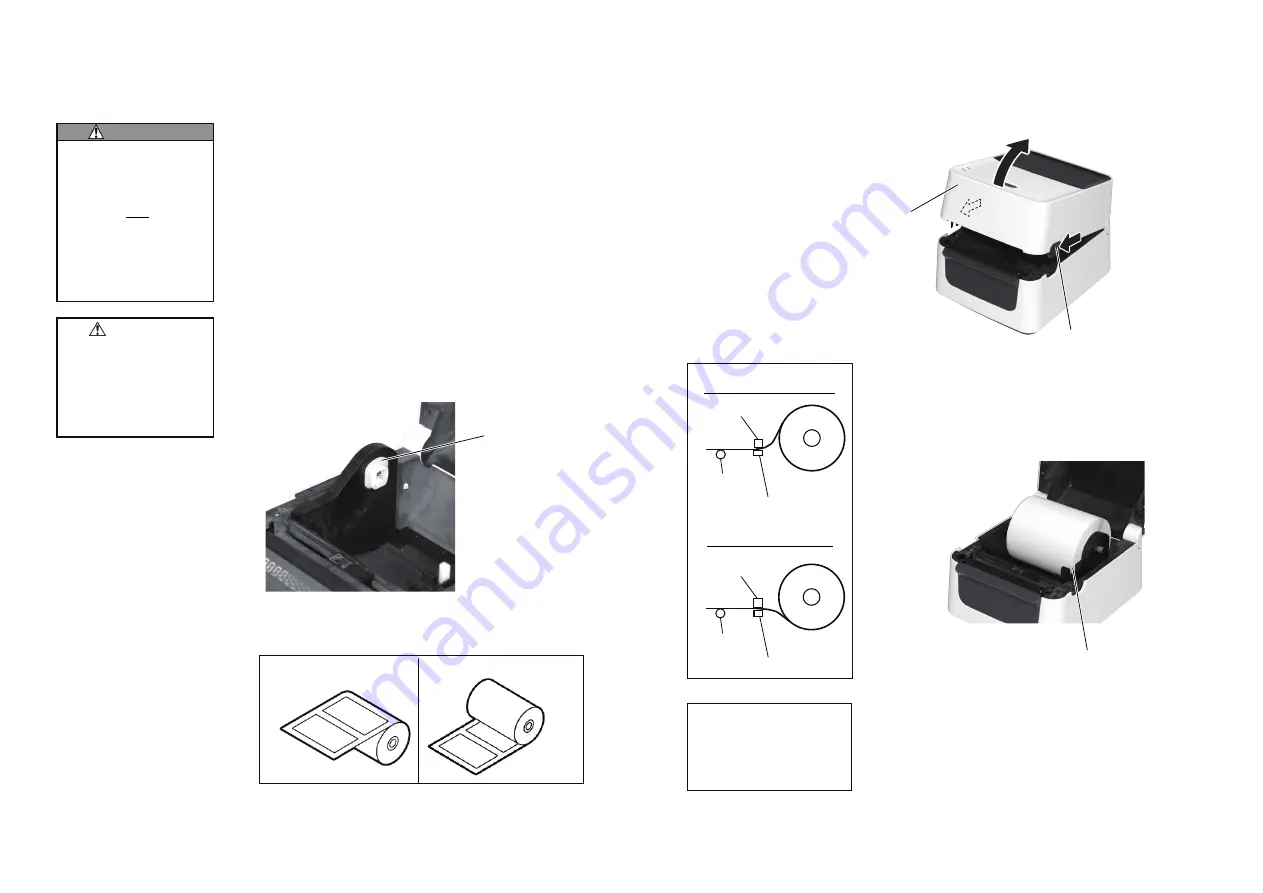

4. Loading

the

Media

This section describes how to load the media in the printer. This

printer accepts label rolls, tag rolls, and fanfold paper stocks. Please

use TOSHIBA TEC CORPORATION approved media.

NOTES:

1. Please perform a media sensor calibration whenever you change the

media type.

For instructions on how to perform a media sensor calibration, refer to

2.9.1 Media Sensor Calibration

of the Owner’s Manual.

2. The size of the media which can be loaded inside the printer is as

follows:

Outer roll diameter: Max. 127mm (5”)

Inner core diameter: 25.4 (1”) mm or 38.1 mm (1.5”)

When the outer roll diameter exceeds 127 mm or the inner core

diameter exceeds 38.1 mm, an optional External Media Stand is

required. For details, refer to the

Installation Manual for the B-FV904-

PH-QM-R External Media Stand

.

At factory shipment, the core holder size is set for 1.5" on the Media

Roll Holders. If you want to use 1" core media, detach the core holders

by loosening the thumb screws, reverse the core holders then re-attach

them with the thumb screws to the Media Roll Holders as shown below.

3. Media rolls can be wound inside or wound outside. (See the diagram

below.) Both types of media roll should be loaded so that the print side

faces up.

WARNING!

1. Do not touch any moving

parts. To reduce the risk of

fingers, jewellery, clothing,

etc. being drawn into the

mechanism, be sure to load

the media

only

once the

printer has completely

stopped moving.

2. To avoid injury, be careful

not to trap your fingers

while opening or closing

the Top Cover.

CAUTION!

Be careful not to touch the

Print Head Elements when

opening the Top Cover. Doing

this may cause damage to

some of the dots through

static discharge or other print

quality problems.

Outside wound

Inside wound

Core Holder

E-8

1.

Open the Top Cover while pulling the Lock Release Portions as

indicated by the arrows.

2.

Open the Media Roll Holders by pressing the Holder Lock Lever

and slide them outward. Place the media roll between the holders

ensuring that print side is facing up, then using Holder Lock Lever

slide the Media Roll Holders to clamp the media roll tightly.

NOTE:

Media path

For the outside-wound media

For the inside-wound media

NOTES:

1. Make sure that the print side

faces up.

2. Cut the leading edge of the

media straight with scissors.

Top Cover

Platen

Feed Gap Sensor

Platen

Feed Gap Sensor

Black mark sensor

Lock Release Portion

Holder Lock Lever

Black mark sensor