APPENDIX 1 SPECIFICATIONS

ENGLISH VERSION EO1-33097

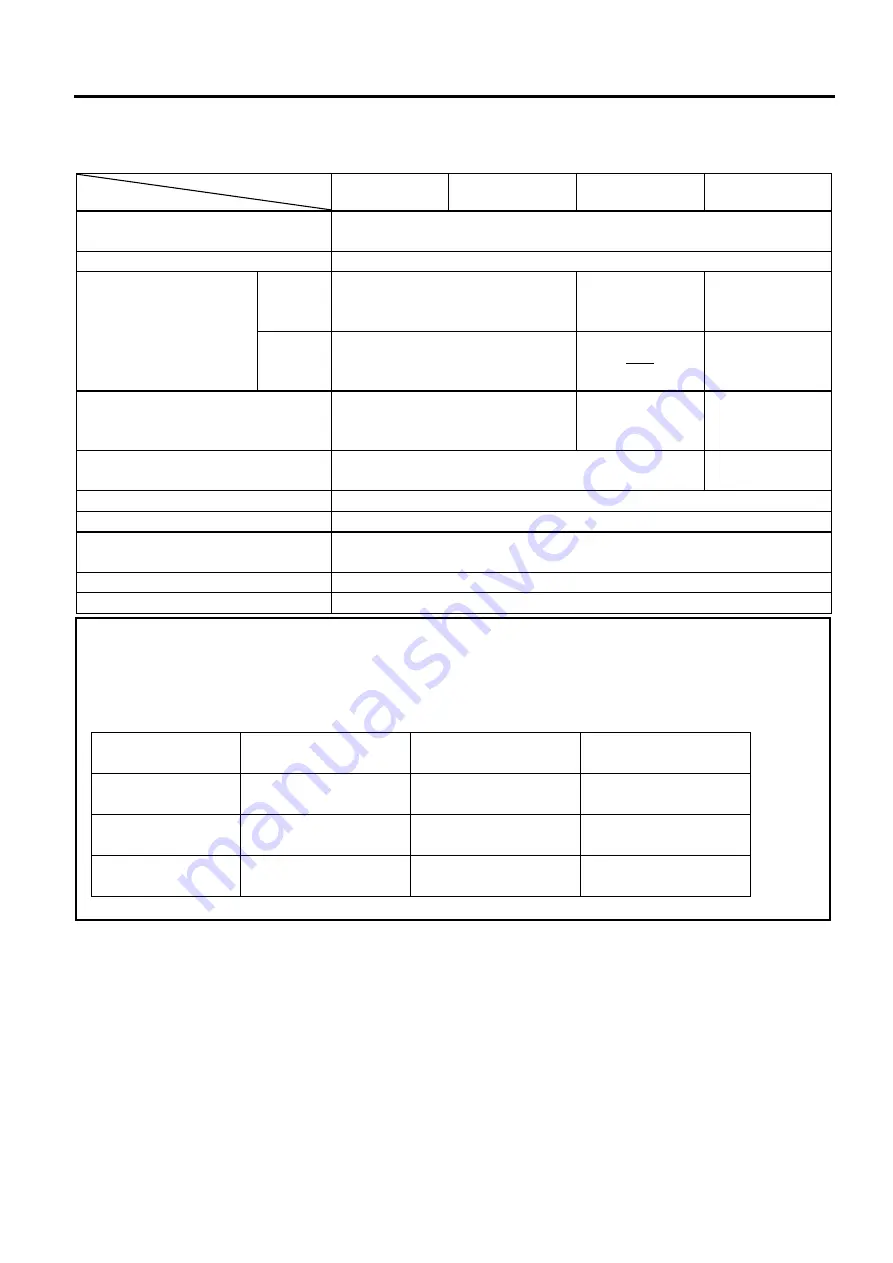

A1.3 Media

EA1-4

A1.3.1 Media Type (Cont.)

Unit: mm (inch)

Issue mode

Item

Batch mode

Batch mode

(Tear-off)

Strip mode

Cut mode

Media width

(Including backing paper)

25.4 to 118.0 (1.00 to 4.65)

Label

width

22.4 to 115.0 (0.88 to 4.53)

Media pitch

Label

10 to 999

(0.39 to 39.3)

See NOTE 3.

25.4 to 152.4

(1.0 to 6.0)

See NOTE 3.

25.4 to 999

(1.0 to 39.3)

See NOTE 3.

Tag

10 to 999

(0.39 to 39.3)

See NOTE 3.

-----

25.4 to 999

(1.0 to 39.3)

See NOTE 3.

Label length

8 to 997

(0.31 to 39.2)

See NOTE 3.

23.4 to 150.4

(0.92 to 5.92)

See NOTE 3.

19.4 to 993

(0.76 to 39.1)

See NOTE 3.

Gap/black mark length

2.0 to 10.0 (0.08 to 0.39)

6.0 to 10.0

(0.24 to 0.39)

Black mark width

Min. 8.0 (0.31)

Thickness

0.06 to 0.19 (0.0024 to 0.0075)

Max. outer roll diameter

Ø

127 (5.0)

Ø

203.2 (8.0): When the optional External Media Stand is used.

Roll direction

Outside (standard), Inside

(

See NOTE.3)

Inner core diameter

25.4, 38.1, or 76.2 (1.0, 1.5, or 3.0)

(

See NOTE 2, 3

.)

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC CORPORATION approved media.

2. When using a media roll of 76.2-mm (3”) inner core diameter, the 3”-Diameter Media Shaft included in the

optional External Media Stand is required.

3. When you use inside wound media, the specifications are restricted as follows:

Unit: mm (inch)

Issue mode

Batch mode

/

Batch mode (Tear-off)

Strip mode

Cut mode

Media pitch

10 to 999

(0.39 to 39.3)

25.4 to 86.2

(1.0 to 3.39)

25.4 to 82.2

(1.0 to 3.24)

Label length

8 to 997

(0.31 to 39.2)

23.4 to 76.2

(0.92 to 3.0)

19.4 to 76.2

(0.76 to 3.0)

Inner core diameter

38.1 or 76.2

(1.5 or 3.0)

38.1 or 76.2

(1.5 or 3.0)

76.2

(3.0)