1. PRODUCT OVERVIEW

ENGLISH VERSION EO1-33114

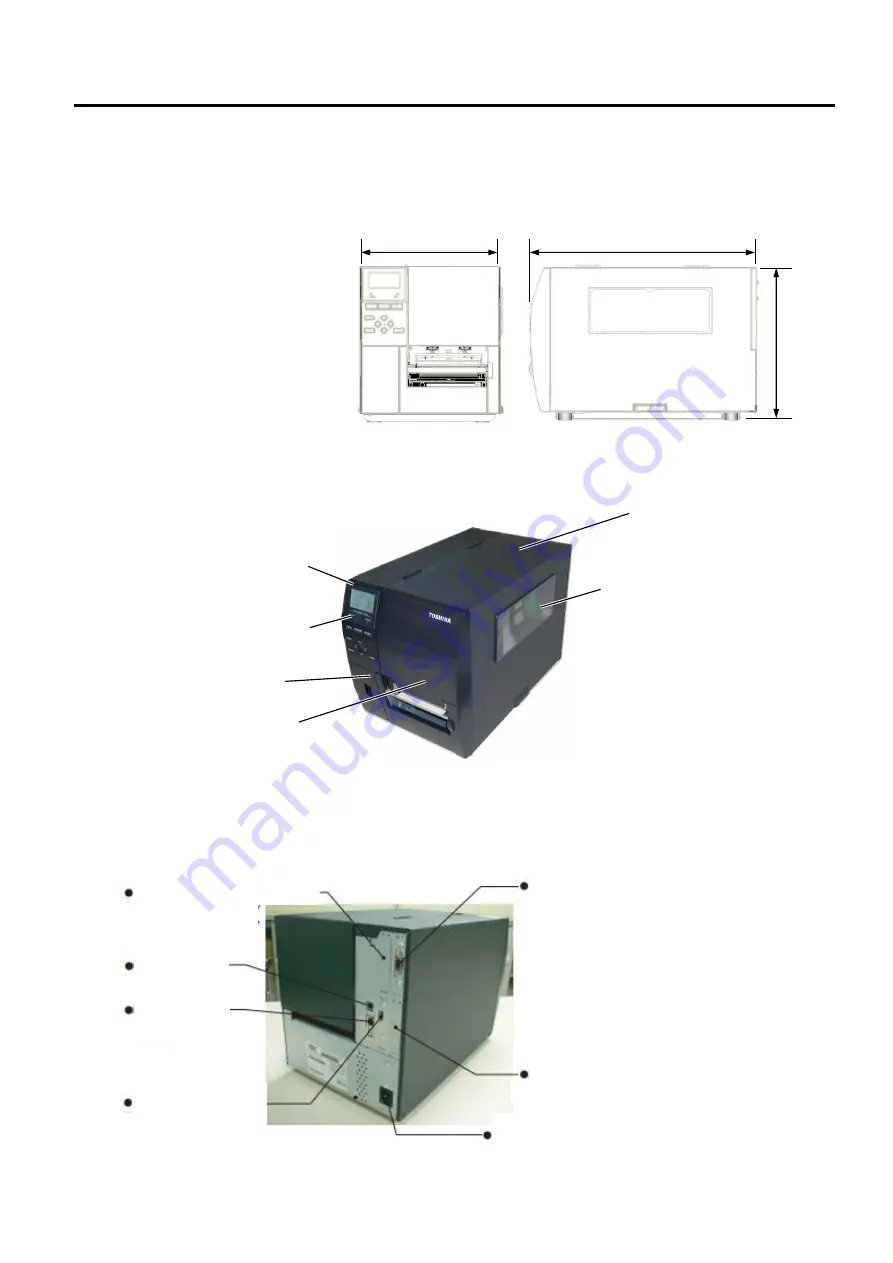

1.5 Appearance

3

1.4 Appearance

1.4.1 Dimensions

1.4.2 Front

View

1.4.3 Rear

View

The names of the parts or units introduced in this section are used in the

following chapters.

278 (10.9)

460 (18.1)

Dimensions in mm (inches)

310

(12.2)

Top Cover

Media Outlet

Supply Window

LCD Message Display

Operation Panel

Serial Port

USB Port

Parallel Port (Option)

LAN Port

USB Host Port

(

Option

)

Expansion I/O (Option)

Power inlet

Power switch