TOSHIBA

6F3A4508

- 7 -

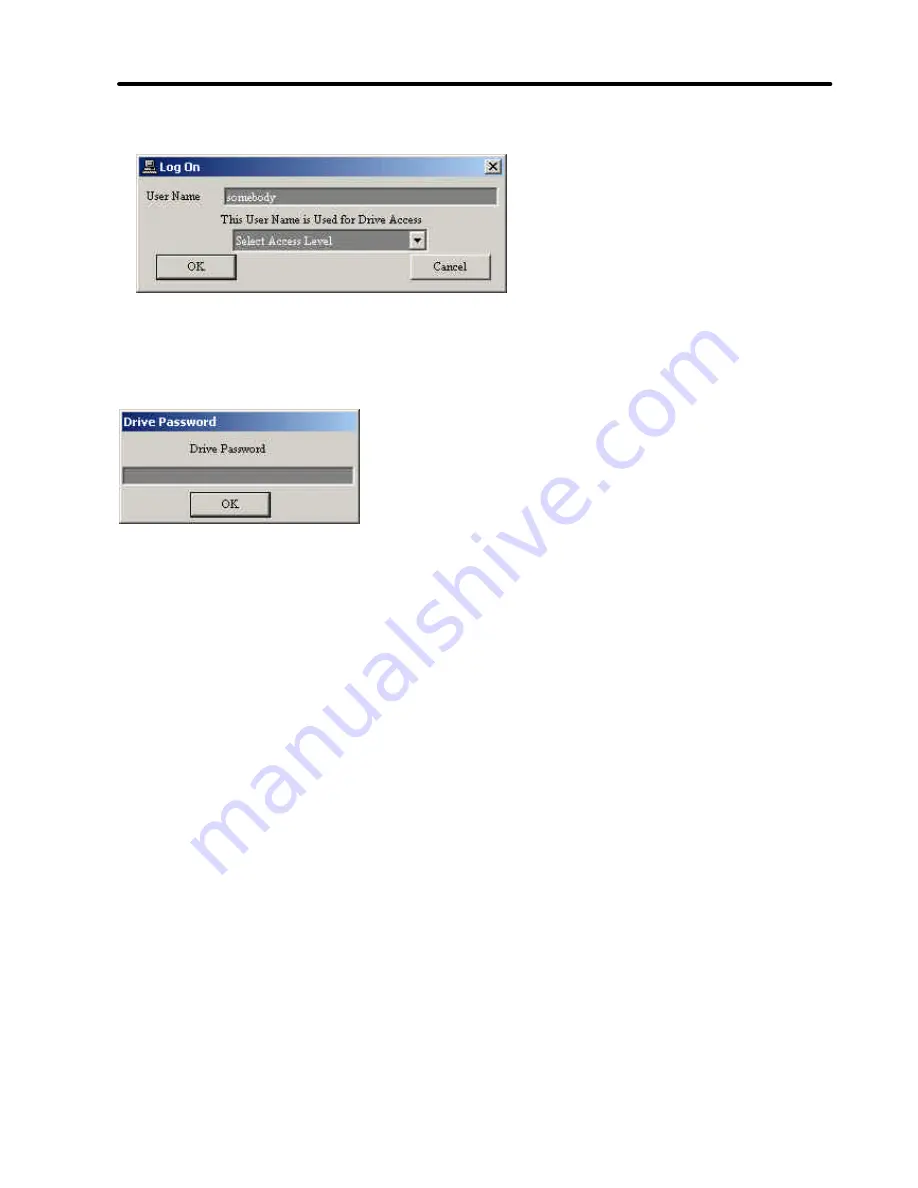

The following window appears when

W

i

Tool

is started.

Figure 3.2 Logon window

Enter the

User Name

and

Access Level

and then click OK.

A password input window appears when connecting to the drive equipment.

Figure 3.3 Password prompt

Enter the password and click OK.

<<User Name, Access Level, Password>>

The name of the operator allowed to connect to the drive equipment, access level of the

operator, and the password for that operator are registered in each drive equipment.

This operator name is referred to as the

User Name

.

The access level is divided into ten levels from 0 (Read Only) to 9 (Full Access).

If the User Name and Access Level do not match those registered in the drive equipment, the

drive equipment returns access level 0.

The User Name and Password are set to "TOSHIBA" at factory shipment.

Access level 9 is allowed with this user name.

This User Name and Access Level are entered when starting

W

i

Tool

and are used to

connect to the drive equipment.

Summary of Contents for 6F3A4508

Page 53: ......