Figure 15

1. Rear jacking points

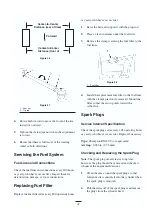

Checking and Adjusting Neutral

When performing routine maintenance and/ or engine

diagnostics, the transaxle must be shifted into neutral

(Fig. 16). The vehicle has a neutral position on the

shift lever, which controls the neutral in the transaxle.

The following steps should be taken to make sure that

the neutral shift lever operates the transaxle neutral

correctly:

1.

Set the shift lever into the Neutral position.

2.

Set the neutral bracket on the transaxle to the

neutral position (level) (Fig. 16).

3.

Tighten one of the locknuts (Fig. 16) just enough

to take the slack out of the shift cable.

Note

: You must hold the locknut below the

bracket to tighten the locknut on top.

4.

Tighten the other locknut just enough to take the

slack out of the other shift cable.

5.

Check the first locknut to make sure that all of

the slack is taken out.

6.

Start the engine and shift into Forward, Reverse,

and Neutral to ensure that the neutral bracket is

operating properly.

Adjusting the Ground Speed

Ground speed is preset at the factory and should not

need adjusting. If you think the ground speed needs

adjusting, contact your local authorized Toro service

dealer.

Figure 16

1. Neutral bracket

2. Locknuts

Servicing the Engine Oil

Service Interval/ Specification

Check the oil level before each use.

Change the oil after the first 20 operating hours and

every 100 operating hours thereafter.

Note:

Change the oil more frequently when operating

conditions are extremely dusty or sandy.

Oil Type:

Detergent oil (API service SG, SH, SJ, or

higher)

Viscosity:

See the table below.

Checking the Oil Level

To check the oil level, refer to

Checking the

Crankcase Oil

.

25

1

1

1

2

Summary of Contents for Workman 1100

Page 36: ......