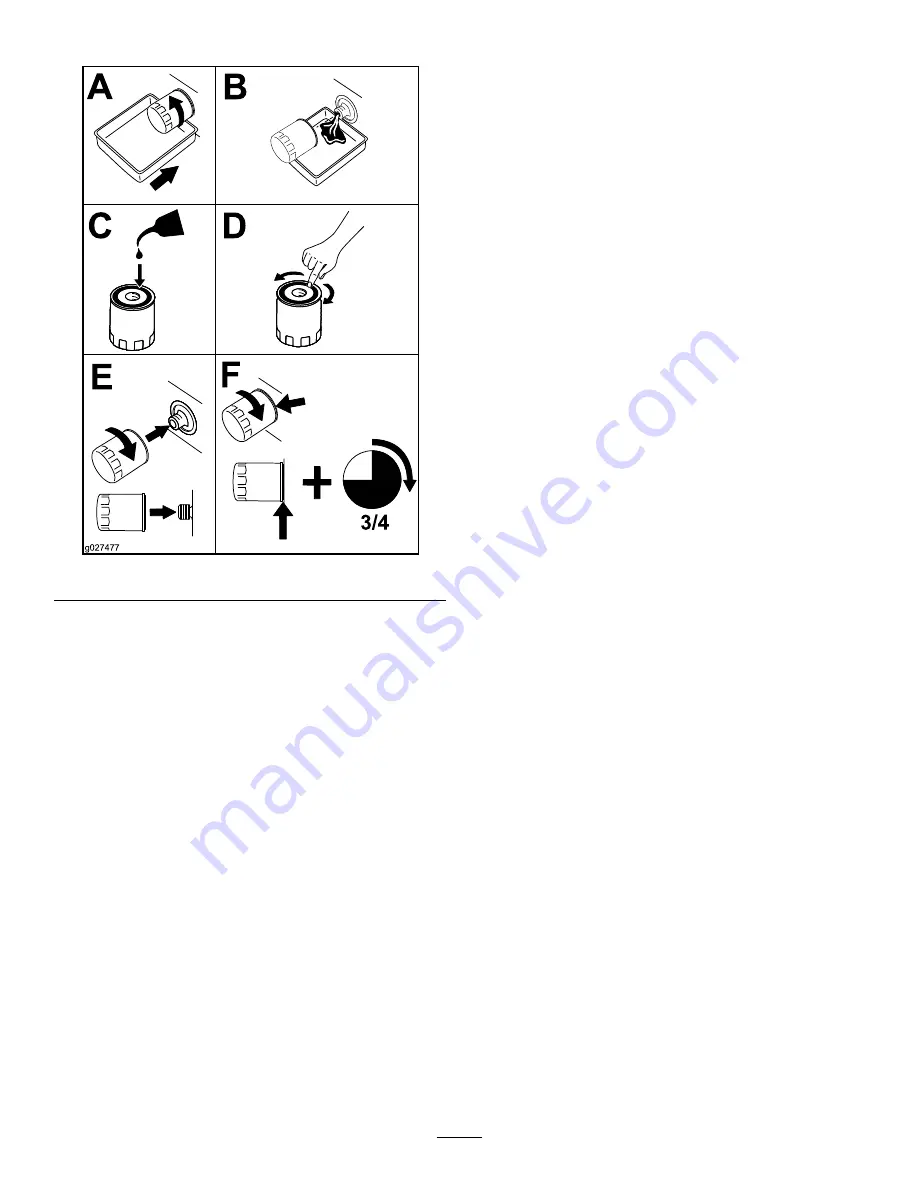

Installing the Hydraulic System Filters

B

A

C

D

E

F

3/4

g027477

Figure 45

1.

Apply a thin coat of the specified oil on the surface of

the rubber seal of each filter.

2.

Turn the filter clockwise until rubber seal contacts the

filter adapter then tighten the filter an additional 3/4 to

1 full turn. Repeat for the other filter

3.

Install the filter guards over each filter as previously

removed. Use the three screws to secure the filter

guards.

4.

Verify the vent plugs are removed before adding the

oil (

5.

Slowly pour the specified oil through expansion

reservoir until oil comes out of

one

of the vent plug

holes. Stop and install that vent plug. Torque the plug

to 20.3 N-m (180 in-lb).

6.

Continue to add oil through the expansion reservoir

until oil comes out of the remaining vent plug hole on

the second transmission. Stop and install that vent

plug. Torque the plug to 20.3 N-m (180 in-lb).

7.

Continue to add oil through the expansion reservoir

until it reaches the Full Cold line on the expansion

reservoir.

8.

Proceed to the Bleeding the Hydraulic System section.

Important:

Failure to perform the

Bleeding

the Hydraulic System procedure after changing

hydraulic filters and oil can result in irreparable

damage to the transaxle drive system.

Bleeding the Hydraulic System

1.

Enter the operator's position. Start engine and

move throttle control ahead to 1/2 throttle position.

Disengage parking brake.

A.

Move the bypass levers into the pushing the

machine position; refer to

. With the bypass valves open

and the engine running, slowly move the motion

control pedal in both forward and reverse (5 or

6 times).

B.

Move the bypass levers into the operating

the machine position. With the bypass valve

closed and the engine running, slowly move the

traction-control pedal in both forward and reverse

directions (5 to 6 times).

C.

Stop the engine and check the oil level in the

expansion reservoir. Add the specified oil as until

it reaches the Full Cold line on the expansion

reservoir.

2.

Repeat step

until all the air is completely purged from

the system.

When the transaxle operates at normal noise levels and

moves smoothly forward and reverse at normal speeds,

then the transaxle is considered purged.

3.

Check the oil level in the expansion reservoir one last

time. Add the specified oil as until it reaches the Full

Cold line on the expansion reservoir if necessary.

38

Summary of Contents for TimeCutter SWX 5050

Page 50: ...Schematics Electrical Diagram Rev A 50 ...

Page 51: ...Notes 51 ...