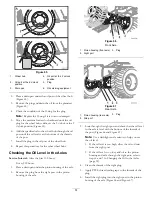

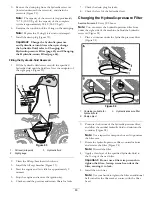

Figure 65

1.

Wheel hub

4.

Oil port at the 3 o’clock

position

2.

Oil port at the 6 o’clock

position

5.

Plug

3.

Drain pan

6.

Oil servicing equipment

2.

Place a drain pan under the oil port of the wheel hub

(Figure 65).

3.

Remove the plug and drain the oil from the planetary

(Figure 65).

4.

Check the condition of the O-ring for the plug.

Note:

Replace the O-ring if it is worn or damaged.

5.

Move the machine forward or backward until the oil

plug for the wheel hub is either at the 3 o’clock or the 9

o’clock position (Figure 65).

6.

Add the specified oil to the wheel hub through the oil

port until the oil level is at the bottom of the threads

of the port.

7.

Install the plug in the oil port of the wheel hub.

8.

Repeat this procedure for the other wheel hubs.

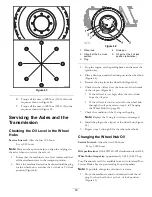

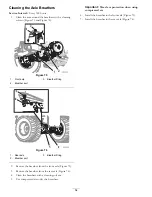

Checking the Oil Level in the Axles

Service Interval:

After the first 100 hours

Every 250 hours

1.

Place a drain pan under the pinion housing of the axle.

2.

Remove the plug from the sight port in the pinion

housing of the axle.

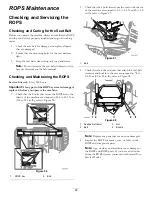

Figure 66

Front Axle

1.

Pinion housing (front axle)

3.

Plug

2.

Sight port

Figure 67

Rear Axle

1.

Pinion housing (rear axle)

3.

Plug

2.

Site port

3.

Look through the sight port and check that the oil level

in the axle is level with the bottom of the threads of

the port (Figure 66 and Figure 67).

Note:

Use a flashlight and a mirror to help you see

the oil level.

•

If the oil level is too high, allow the oil to drain

from the sight port.

•

If the oil level is too low, add oil to the pinion

housing and axle through the sight port; refer to

steps 6 and 7 in Changing the Oil in the Axles

(page 52).

4.

Clean the threads of the sight plug.

5.

Apply PTFE thread sealing tape to the threads of the

plug.

6.

Install the sight plug into the sight port in the pinion

housing of the axle (Figure 66 and Figure 67).

51

Summary of Contents for RT600

Page 71: ...Notes 71...