4.

To prevent a fire hazard, wipe up any fuel that

may have spilled.

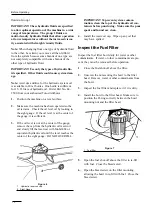

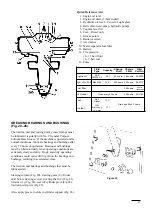

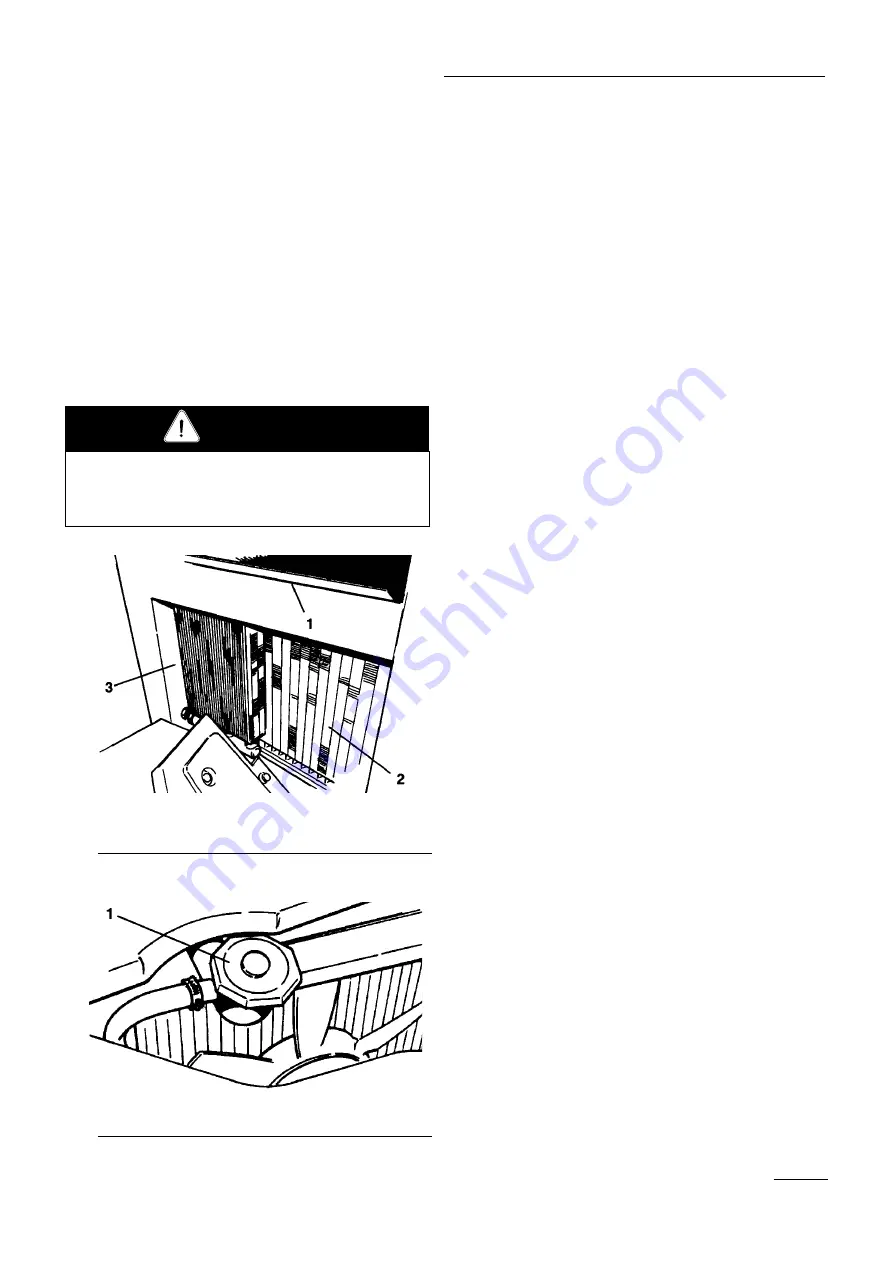

Check the Cooling System

Clean debris off the radiator screen, radiator and oil

cooler daily (Fig. 4), or hourly if conditions are

extremely dusty and dirt.

The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti-freeze.

Check the level of coolant at the beginning of each

day before you start the engine. Capacity of the cool-

ing system is 5.0 liters.

Figure 4

1. Radiator screen

2. Radiator

3. Oil cooler

Figure 5

1. Radiator cap

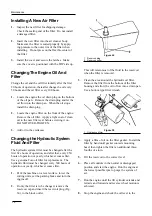

1.

Carefully remove the cap from the radiator.

2.

Check the level of coolant in the radiator. The

radiator should be filled to the top of the filler

neck.

3.

If the coolant level is low, replenish the system.

DO NOT OVERFILL.

4.

Install the radiator cap.

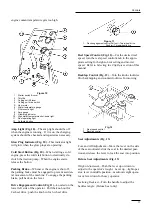

Check The Hydraulic System Fluid

The hydraulic system is designed to operate on anti-

wear hydraulic fluid. The machine’s system is filled at

the factory with approximately 12.5 liters of fluid.

However, check the level of hydraulic fluid before you

first start the engine and daily thereafter.

Group 1—Hydraulic Fluid (Recommended for

ambient temperatures consistently below 37° C.)

ISO-type 46/68 anti-wear hydraulic fluid

Mobil

Mobil Fluid 424

Shell

Donax TD

Amoco

Amoco 1000

Conoco

Power Tran 3

International Harvester

Hy-Tran

Texaco

TDH

Exxon

Torque Fluid

Kendall

Hyken 052

BP Oil

BP HYD TF

Boron Oil

Eldoran UTH

Phillips

HG Fluid

Union Oil

Hydraulic/Tractor

Fluid

Chevron

Tractor Hydraulic

Fluid

Note: All are interchangeable.Group 2—Hydraulic

Fluid (Biodegradable):

ISO VG 32/46 anti-wear hydraulic fluid

Mobil

EAL 224 H

IMPORTANT: Due to the nature of biodegradable

fluids, it is critical that the fluid be changed at the

recommended intervals or severe hydraulic compo-

nent damage may occur.

Note: The fluid in Group 2 is not compatible with the

11

Before Operating

If the engine has been running, pressurized hot

coolant can escape when the radiator cap is

removed and cause burns.

WARNING