Maintenance

Note:

Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first hour

• Check the control cable and adjust it if necessary.

• Check for loose fasteners and tighten them if necessary.

After the first 2 hours

• Change the engine oil.

Before each use or daily

• Check the engine oil level and add oil if necessary.

Yearly

• Check the control cable and adjust it if necessary.

• Inspect the rotor blades and have an Authorized Service Dealer replace the rotor

blades and scraper if necessary.

• Change the engine oil.

• Service the spark plug and replace it if necessary.

• Check for loose fasteners and tighten them if necessary.

• Have an Authorized Service Dealer inspect the drive belt and replace it if necessary.

Yearly or before storage

• Prepare the machine for storage.

Adjusting the Control Cable

Refer to Adjusting the Control Cable in Setup.

Inspecting the Rotor Blades

Service Interval:

Yearly—Inspect the rotor blades and have

an Authorized Service Dealer replace the

rotor blades and scraper if necessary.

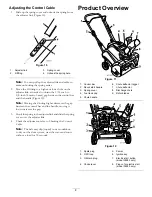

Before each session, inspect the rotor blades for wear. When

a rotor blade edge has worn down to the wear indicator hole,

have an Authorized Service Dealer replace the rotor blades

and the scraper (Figure 27).

Figure 27

1.

The wear indicator hole is

intact; you do not need to

replace the rotor blades.

3.

Scraper

2.

The wear indicator hole is

exposed; replace the rotor

blades and scraper.

Changing the Engine Oil

Service Interval:

After the first 2 hours

Yearly

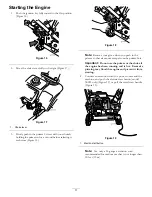

Run the engine a few minutes before changing the oil to warm

it. Warm oil flows better and carries more contaminants.

1.

Ensure that the fuel tank is not overfilled (refer to

Figure 13) and that the fuel cap is securely in place.

2.

Move the machine to a level surface.

3.

Place an oil drain pan under the oil drain plug

(Figure 12), remove the oil drain plug, and tip the

machine backward (handle down) halfway to the

ground to drain the used oil into the oil drain pan.

Important:

Do not tip the machine all the way

back to the ground, or fuel may leak out of the

machine.

4.

After draining the used oil, return the machine to the

operating position.

5.

Install the oil drain plug and tighten it securely.

6.

Clean around the oil fill cap (Figure 12).

7.

Unscrew the oil fill cap and remove it.

8.

Slowly

pour oil into the oil fill hole. Wait 3 minutes,

then check the oil level on the dipstick by wiping the

dipstick clean and then inserting,

but not screwing in,

the oil fill cap into the hole.

Note:

To determine the proper oil level on the

dipstick, refer to Figure 28.

15

Summary of Contents for Powerlite 38273

Page 18: ...Notes 18...