43

GTS 200

Electric Starter

3. Three (3) screws holding gear cover and gear itself may

now be removed.

4. Lift clutch assembly and pinion gear off their respective

shafts.

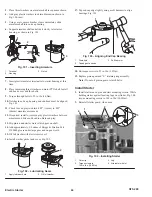

5. Remove starter motor thru bolts, Fig. 97.

1

2

3

Fig. 97 – Removing Thru Bolts

1.

Housing

2.

End cap

3.

Remove thru bolts

6. Separate motor end cap from motor housing.

7. Push motor armature out through bottom of starter

housing, taking care to slide plastic mounted terminal out

of motor housing along with end cap, Fig. 98.

1

4

3

2

Fig. 98 – Removing Armature

1.

Terminal

2.

End cap

3.

Housing

4.

Armature shaft

8. Before removing armature from end cap, check brushes for

freedom of movement.

9. If brushes are found to be sticking in their retainers, this

must be corrected, or poor starter motor performance will

result, Fig. 99.

1

5/64” (2mm)

Fig. 99 – Checking Brushes

1.

Brushes

10. If brushes are worn to a length of 5/64” (2mm) or less,

brushes should be replaced.

11. Check brush springs for proper tension (sufficient force

to keep brush in firm contact with commutator).

Clean and Inspect Starter

1. Clean all dirt from armature, end cap, motor support,

gears, etc.

2. End cap bearings and armature should not be soaked in a

solvent.

3. Armature commutator may be cleaned with a fine

sandpaper or commutator paper.

Note: Do not use any metallic oxide paper or emery cloth,

as metallic oxide or emery will become embedded in

commutator causing rapid brush wear.

4. If armature is suspected to be defective, a new armature

should be tried in motor.

5. If proper testing equipment is available, check suspected

armature to determine if it is defective.

Starter motor armatures have very low resistance, usually

below detection on available multimeters. To check for

shorted armatures, a piece of equipment known as a “growler”

may be used. If this equipment is not available, a known good

armature should be tried and performance rechecked.

If magnets are loose or cracked, a new motor housing should

be tried.

Assemble Starter Motor

1. When all parts have been thoroughly inspected, lightly

lubricate bearings with an oil made for use in electric

motors and reassemble in following manner.

2. Insert brush springs and brushes in holders as far as

possible, and hold them in this position with tool shown in

Figs. 89 and 100.

1

3

2

1

5

4

.225”

(5.72mm)

.200”

(5.1mm)

Fig. 100 – Armature Assembly to End Cap

1.

Gray plastic washers

2.

Armature

3.

Brush spreader

4.

.176” (4.47mm) thick fiber

washer

5.

.030” (.76mm) thick steel

washer