Product Overview

G010001

1

2

3

4

5

6

7

8

9

10

Figure 4

1.

Motion control levers

4.

Fuel gauge

7.

Anti-scalp roller

10.

Control panel

2.

Operator seat

5.

Footrest

8.

Deflector

3.

Parking brake

6.

Front caster wheel

9.

Foot pedal deck lift and

height-of-cut

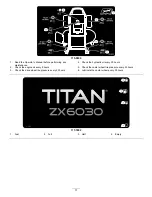

G010009

1

2

3

4

5

6

Figure 5

1.

Gas tank cap

3.

Washout port

5.

Engine guard

2.

Mower Deck

4.

Drive wheel

6.

Engine

12

Summary of Contents for 74833

Page 50: ...Schematics G012083 Wire Diagram Rev B 50...

Page 51: ...Notes 51...