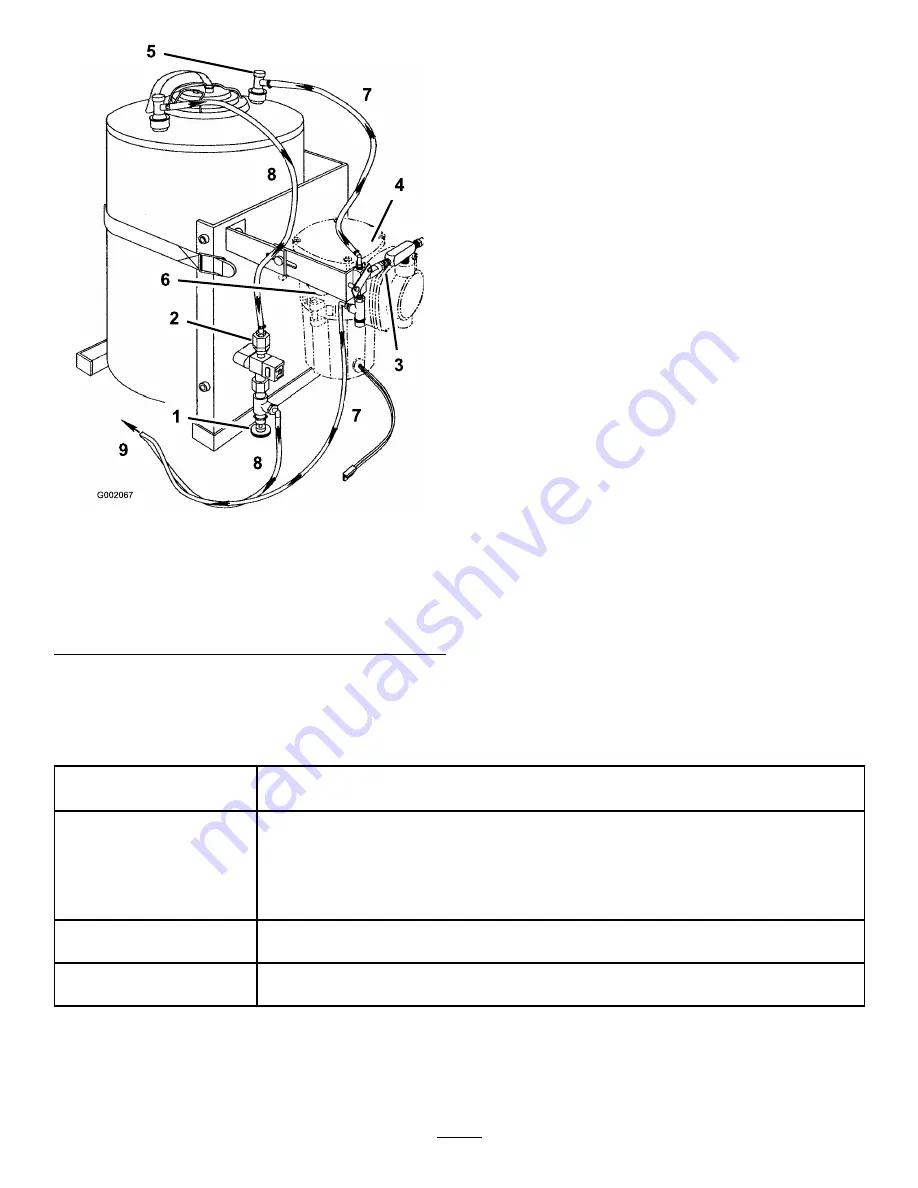

Figure 33

1.

Foam density adjustment

valve

6.

Air filter

2.

Strainer

7.

Air only

3.

Check valve

8.

Liquid

4.

Compressor

9.

To mixer tee

5.

Couplers

9. Start operating the marking system and make a test

pattern on the ground. When you first start the

marking system, allow 1 to 2 minutes for the foam

to flow through the line.

10. Adjust the foam density adjustment valve to obtain

the desired consistency and spray as normal.

Note:

If you leave the foam in the line for more

than 2 hours, it may become watery. Before

operating after a break of 2 or more hours, run the

machine for 1 to 2 minutes to remove the excess

water.

Note:

The mixer tee can flood if the solution-to-air

mixture is too rich, producing watery foam. If the

foam is too dry, the flow will be unsteady with

high-pressure surges.

If the foam in the machine is very watery, do the

following:

A. Close the foam density adjustment valve

completely.

B. Operate for 2 minutes.

C. Wait 1 minute and then check the consistency

of the foam.

D. Adjust the foam to achieve the desired

consistency.

Maintenance

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

Every 100 hours

• Inspect the hose between the foam tank and the compressor for accumulated water.

• Inspect and clean the check valve in the tee on top of the compressor. Replace

the valve if necessary.

• Remove and clean the strainer at the top of the solenoid valve, next to the

compressor.

• Ensure that the bottom of the compressor is free from debris.

Every 250 hours

• Replace the compressor air filter.

• Check for and rinse out debris from the inside of the tank.

Every 500 hours

• Replace the plastic check valve at the “Y” near the mixer tee assembly, located at

the rear of the machine, on the center boom.

Cleaning the Strainer

Important:

Dried foam agent and debris can

clog the strainer (Figure 34), causing slow or no

foam production. This can be mistaken for a bad

foam pump or incorrect foam mix. If experiencing

15