Inspecting the Transmission

Control Cable and Operating

Mechanism

Service Interval:

Every 250 hours

Check the condition and security of the cable and operating

mechanism at the speed-control pedals and transmission

pump ends.

•

Remove buildup of dirt, grit and other deposits.

•

Ensure that the ball joints are securely anchored and

check that the mounting brackets and cable anchors are

tight and free from cracks.

•

Inspect end fittings for wear, corrosion, broken springs,

and replace if necessary.

•

Ensure that the rubber seals are correctly located and are

in good condition.

•

Ensure that the articulating sleeves supporting the inner

cable are in good condition and firmly attached to the

outer cable assembly at the crimped connections. If there

are any signs of cracking or detachment install a new

cable immediately.

•

Check that sleeves, rods, and inner cable are free from

bends, kinks, or other damage. If they are not, install a

new cable immediately.

•

With the engine shut off, operate the pedal controls

through the entire range and ensure that the mechanism

moves smoothly and freely to the neutral position without

sticking or hanging up.

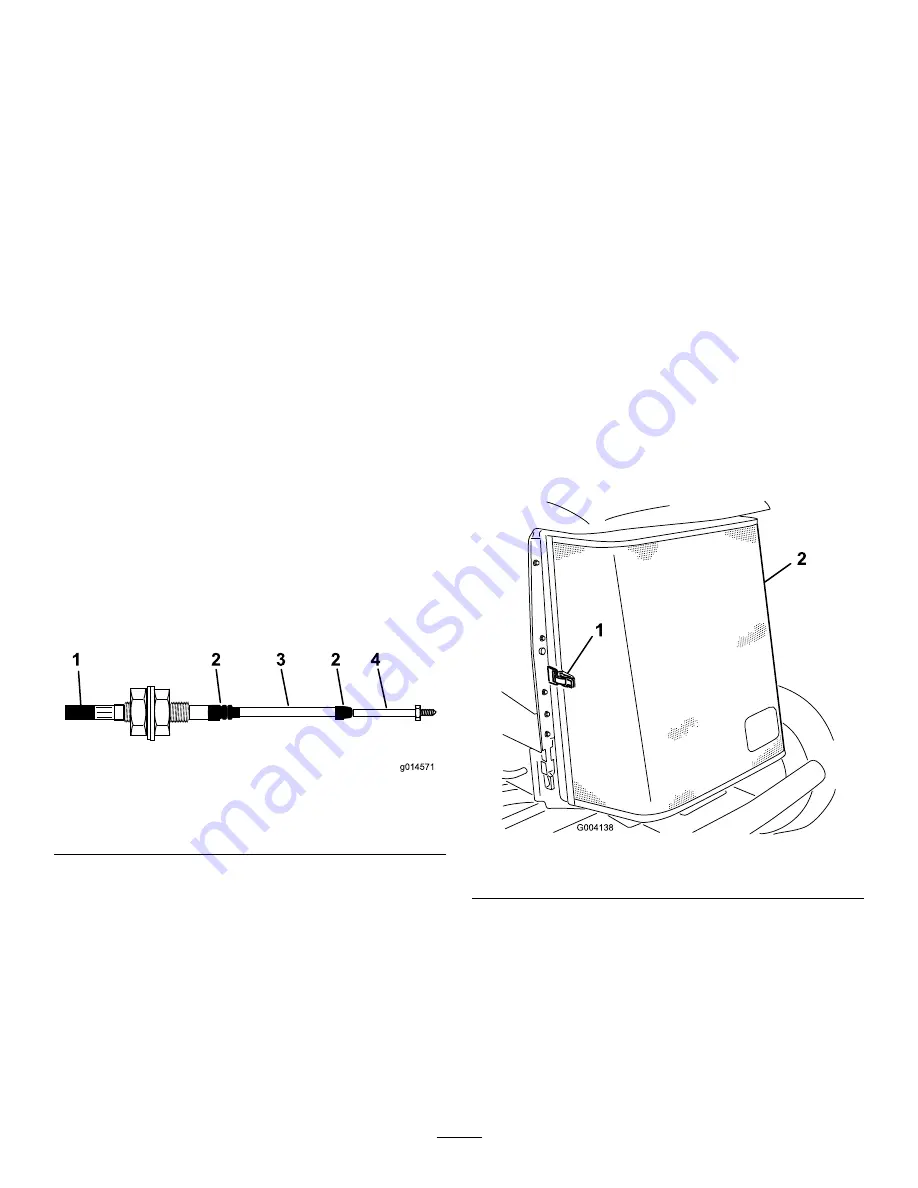

g014571

1 2 3 2 4

Figure 58

1.

Outer cover

3.

Sleeve

2.

Rubber seal

4.

Rod end

Cooling System

Maintenance

Removing Debris from the

Cooling System

Service Interval:

Before each use or daily

Every 100 hours

Every 2 years

Note:

To prevent the engine from overheating, the radiator

and oil cooler must be kept clean. Normally, check daily and,

if necessary, clean any debris off these parts. However, it is

necessary to check and clean more frequently in extremely

dusty and dirty conditions.

1.

Turn the engine off and remove the key from the

ignition switch.

2.

Thoroughly clean all debris out of the engine area.

3.

Unlatch the clamp and pivot open the rear screen

(

).

Figure 59

1.

Rear screen latch

2.

Rear screen

4.

Clean the screen thoroughly with compressed air.

5.

Pivot the latches inward to release the oil cooler (

45