8.

Release the rocker switch to proceed to the next

step in the sequence (

).

g231715

Figure 17

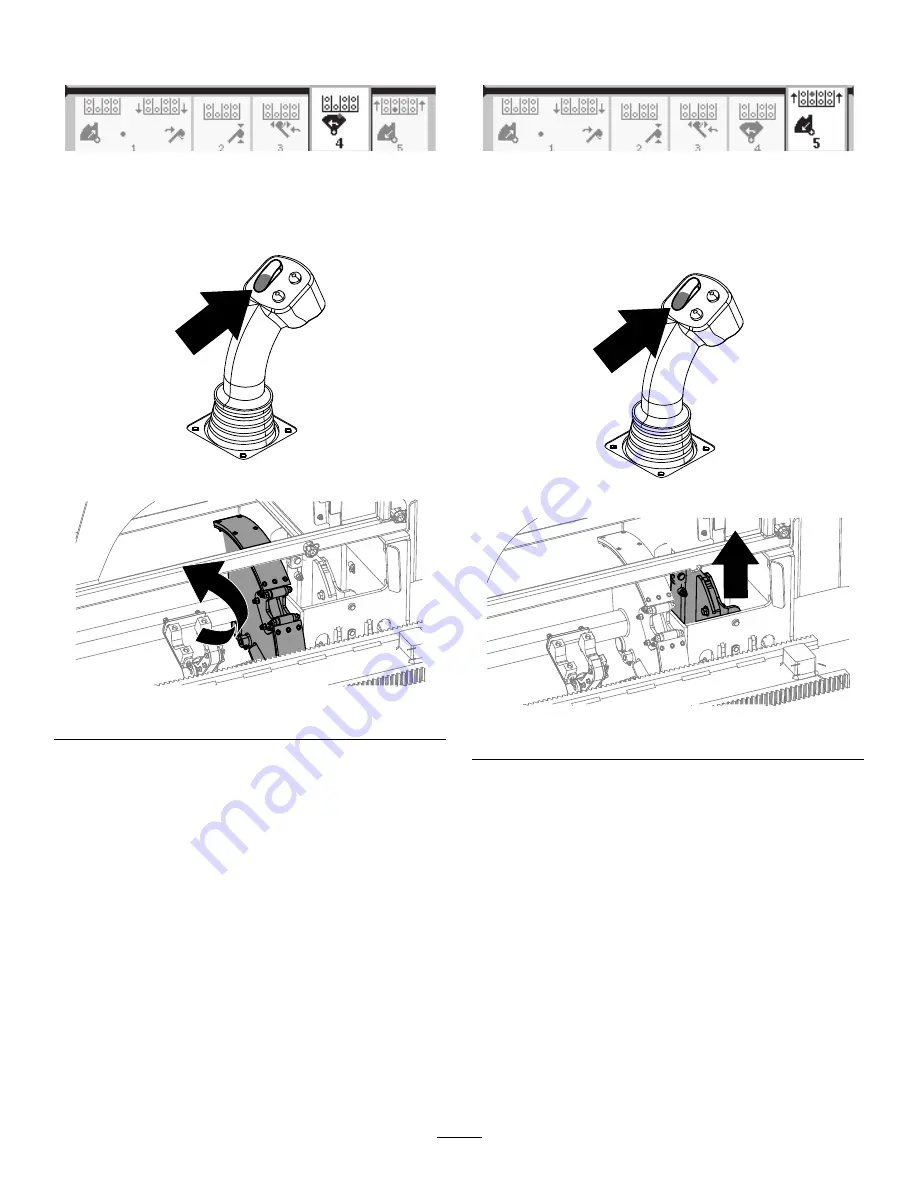

9.

Hold the lower section of the rocker switch

(

) until the cam assembly rotates to the

selected row under the pipe box (

g210462

Figure 18

g232379

Figure 19

10.

Release the rocker switch to proceed to the next

step in the sequence (

).

g231716

Figure 20

11.

Hold the lower section of the rocker switch

(

) until the elevator puts the pipe back

in the pipe box and the cam rotates to the home

position (

g210462

Figure 21

g232380

Figure 22

12.

Release the rocker switch to start the pull-pipe

process again.

5