4

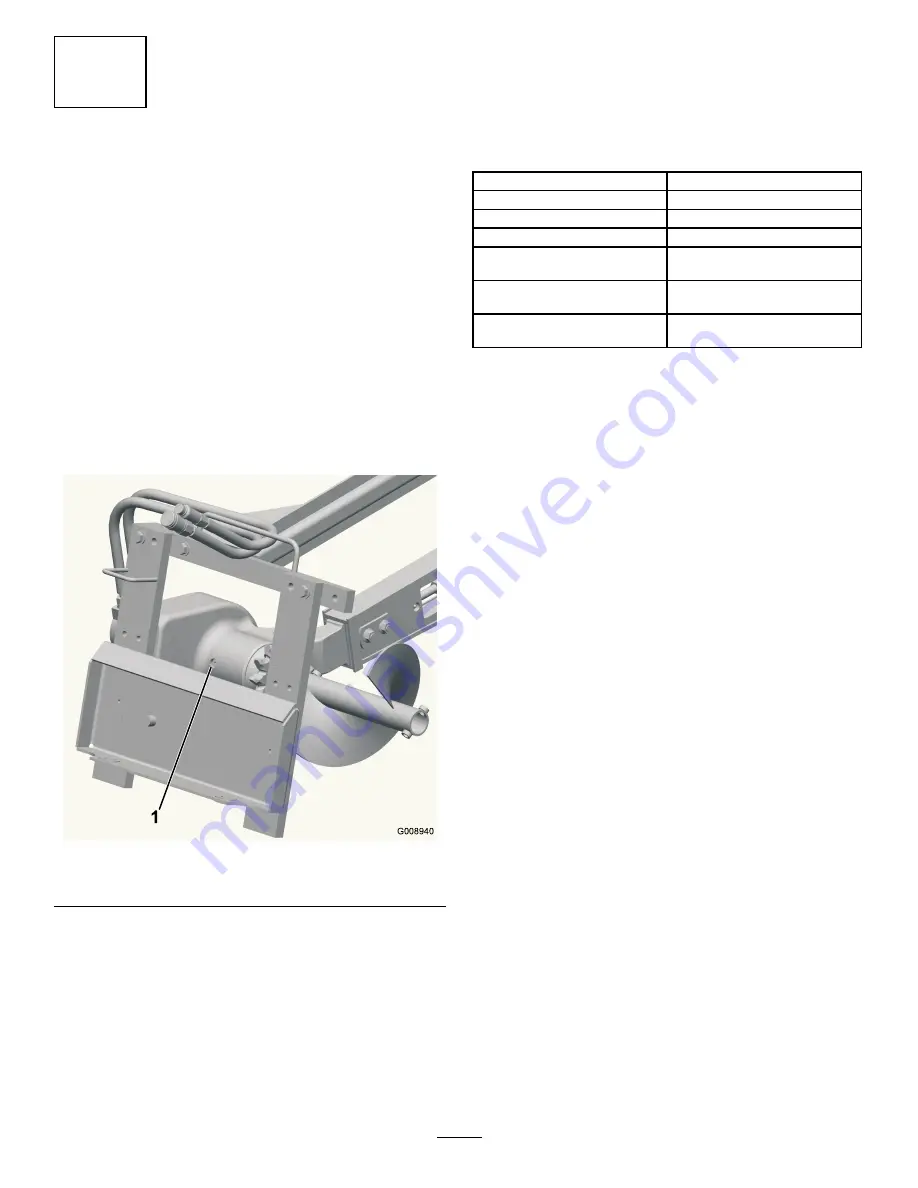

Checking the Bearing Case

Lube Level

No Parts Required

Procedure

Before operating the trencher, check to ensure that the

bearing case is filled with gear lube.

1. Lower the trencher to the ground on a flat, level

surface and tilt it so that the boom is parallel with

the ground.

2. Stop the engine and remove the key.

3. Clean the area around the bearing case fill hole plug

G008940

1

Figure 6

1.

Bearing case fill hole plug

4. Remove the plug from the bearing case fill hole

5. Look in the hole, the level should be up to the

bottom of the hole; if not add gear lube until it

comes out of the hole.

6. Replace the plug and torque it to 15 to 17 ft-lb (20

to 23 N-m).

Product Overview

Specifications

Note:

Specifications and design are subject to change

without notice.

Width, with 3 ft (91 cm) boom

35 inches (89 cm)

Length, with 3 ft (91 cm) boom 65 inches (165 cm)

Height, with 3 ft (91 cm) boom

24 inches (61 cm)

Weight, with 3 ft (91 cm) boom 390 lb (177 Kg)

Maximum trench depth, 2 ft (61

cm) boom

24 inches (61 cm) at a 65

degree boom angle

Maximum trench depth, 3 ft (91

cm) boom

36 inches (91 cm) at a 65

degree boom angle

Maximum trench depth, 4 ft

(122 cm) boom

48 inches (122 cm) at a 65

degree boom angle

Attachments/Accessories

A selection of Toro approved attachments and

accessories are available for use with the machine to

enhance and expand its capabilities. Contact your

Authorized Service Dealer or Distributor or go to

www.Toro.com for a list of all approved attachments

and accessories.

8