Drive System

Maintenance

Servicing the Tracks

Service Interval:

After the first 50 hours—Check and adjust

the track tension.

Before each use or daily—Clean the tracks.

Before each use or daily—Check the tracks for

excessive wear and proper tension.

Every 100 hours—Check and adjust the track tension.

Cleaning the Tracks

1.

Park the machine on a level surface and engage the

parking brake.

2.

With the bucket installed and pointing down, lower it

into the ground so that the front of the traction unit

lifts off the ground a few centimeters (inches).

3.

Shut off the engine and remove the key.

4.

Using a water hose or pressure washer, remove dirt

from each track system.

Important:

Ensure that you use high-pressure water to

wash only the track area. Do not use a high-pressure

washer to clean the rest of the traction unit. Do not

use high pressure water between the drive sprocket

and the traction unit or you may damage the motor

seals. High-pressure washing can damage the electrical

system and hydraulic valves or deplete grease.

Important:

Ensure that you fully clean the road wheels,

the front wheel, and the drive sprocket (

). The

road wheels should rotate freely when clean.

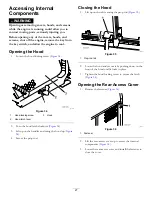

g029756

Figure 57

1.

Track

3.

Drive sprocket

2.

Front wheel

4.

Road wheel

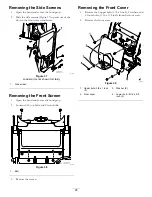

Adjusting the Track Tension

Verify that the tension block is aligned with the green guide

on the decal or that the block is 1.3 cm (1/2 inch) away from

the rear of the tension tube slot (

). If it is not, adjust

the track tension using the following procedure:

g203962

Figure 58

1.

Green guide on decal

2.

Tension block

1.

Park the machine on a level surface, engage the parking

brake, and lower the loader arms.

2.

Shut off the engine and remove the key.

3.

Remove the locking bolt and nut (

g029758

Figure 59

1.

Tension tube

3.

Tensioning screw

2.

Locking bolt

4.

Using a 1/2 inch drive ratchet, turn the tensioning

screw counter-clockwise until the tension block aligns

with the green guide on the decal or is 1.3 cm (1/2 inch)

away from the rear of the tension tube slot (

5.

Align the closest notch in the tension screw to the

locking-bolt hole and secure the screw with the locking

bolt and nut (

6.

Repeat the procedure for the other track.

39

Summary of Contents for 22327

Page 54: ...Schematics g205307 Electrical Schematic Rev B 54...

Page 55: ...g206362 Hydraulic Schematic Rev B 55...

Page 56: ...Notes...

Page 57: ...Notes...

Page 58: ...Notes...