Operation

Note:

Determine the left and right sides of the

machine from the normal operating position.

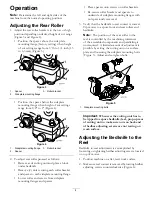

Adjusting the Rear Roller

1. Adjust the rear roller brackets to the low or high

position depending on desired height of cut range

(Figure 3 and Figure 4).

•

Position the spacer above the side plate

mounting flange (factory setting) when height

of cut settings range from 1/16 to 1/4 inch (1.5

to 6.3 mm) (Figure 3).

Figure 3

1.

Spacer

3.

Roller bracket

2.

Side plate mounting flange

•

Position the spacer below the sideplate

mounting flange when height of cut settings

range from 1/8" to 1" (Figure 4).

Figure 4

1.

Sideplate mounting flange

3.

Roller bracket

2.

Spacer

2. To adjust rear roller proceed as follows:

•

Raise rear of cutting unit and place a block

under bedknife.

•

Remove (2) nuts securing each roller bracket

and spacer to each sideplate mounting flange.

•

Lower roller and screws from sideplate

mounting flanges and spacers.

•

Place spacers onto screws on roller brackets.

•

Re-secure roller bracket and spacers to

underside of sideplate mounting flanges with

nuts previously removed.

3. Verify that the bedknife to reel contact is correct.

Tip mower to expose front and rear rollers and

bedknife.

Note:

The position of the rear roller to the

reel is controlled by the machining tolerances

of the assembled components and paralleling is

not required. A limited amount of adjustment is

possible by setting the cutting unit on a surface

plate and loosening the sideplate mounting bolts

(Figure 5). Adjust and re-tighten bolts.

Figure 5

1.

Sideplate mounting bolts

Important:

Whenever the cutting unit has to

be tipped to expose bedknife/reel, prop up rear

of cutting unit to make sure nuts on back end

of bedbar adjusting screws are not resting on

work surface.

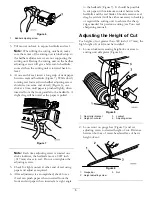

Adjusting the Bedknife to the

Reel

Bedknife to reel adjustment is accomplished by

loosening or tightening bedbar adjusting screws, located

on top of mower.

1. Position machine on a flat, level work surface.

2. Make sure reel contact is removed by turning bedbar

adjusting screws counterclockwise (Figure 6).

4