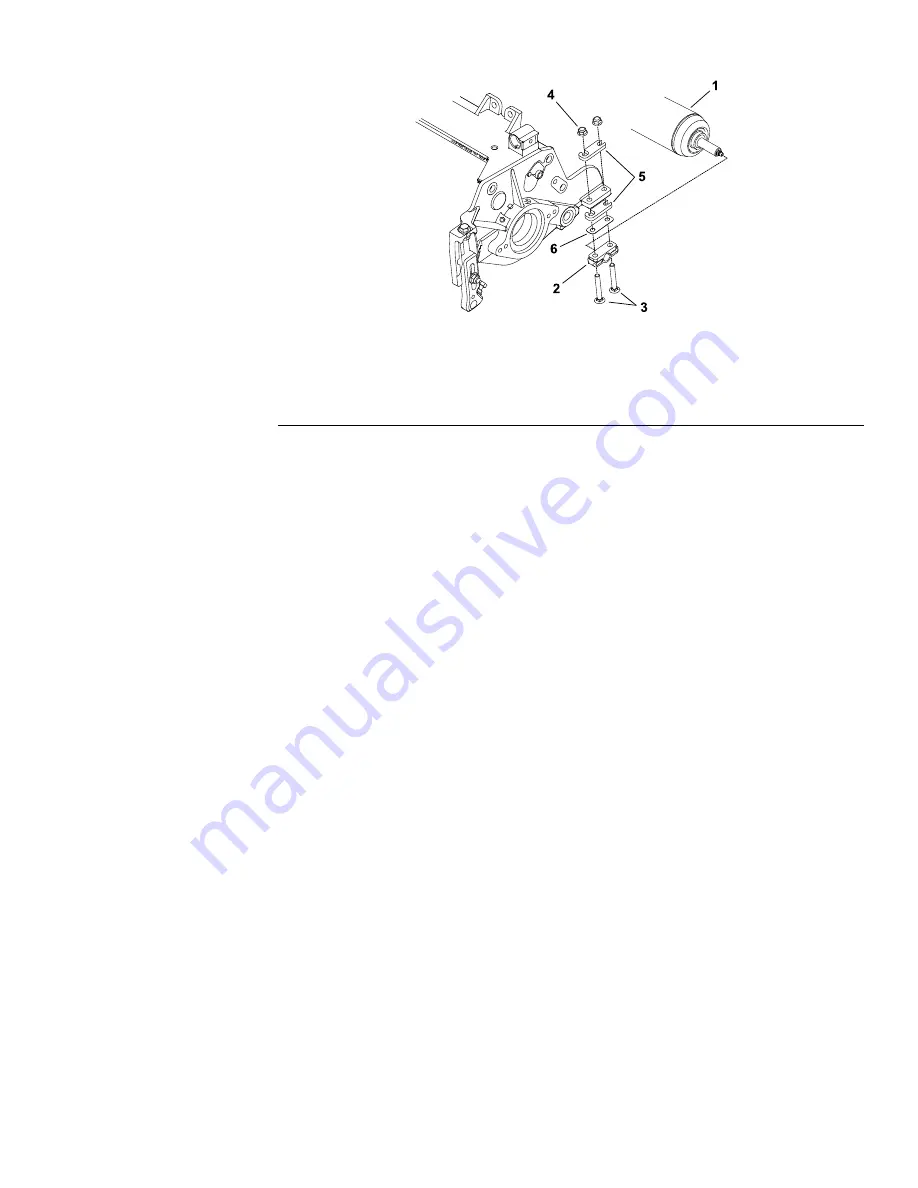

Leveling Rear Roller (continued)

g214395

Figure 164

1.

Rear roller assembly

4.

Flange nut

2.

Rear roller bracket

5.

Roller shim

3.

Carriage screw

6.

0.010” shim (if needed)

7. If rear roller is still not level after adjusting both side plates, check to see if

cutting reel is tapered (refer to

Preparing the Reel for Grinding (page 8–29)

).

If cutting reel is not tapered and rear roller is not level, a 0.010” shim (part

number 107-4001) is available to allow additional rear roller adjustment. The

shim would be used on one side of the rear roller and should be installed

between the rear roller bracket and roller shim (

).

8. After leveling rear roller, complete the cutting unit set-up and adjustment

sequence.

Reelmaster

®

3100-D/3105-D

Page 8–5

DPA Cutting Units: Adjustments

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......