Leveling Rear Roller

The precision machined components of the cutting unit frame keep the rear roller

and cutting reel in alignment (parallel). If the side plates are disassembled or as

the cutting reel wears, a limited amount of side plate adjustment is possible to

make sure that the cutting unit is properly aligned.

1. Place the assembled cutting unit on a surface plate.

2. Make sure that the bedknife is properly adjusted to the cutting reel.

3. Check if the rear roller is level to the cutting reel by using a 0.13 mm (0.005

in) feeler gauge to determine the clearance between the surface plate and

the rear roller at each end of the roller. As the rear roller is rotated one full

turn, check if the feeler gauge will consistently pass under the roller at one

end but will not pass under the opposite end. Check rear roller with the feeler

gauge just inside the machined ends of the roller. A frame adjustment should

be made if there is consistently more than 0.13 mm (0.005 in) clearance

under the roller on one end but not on the other.

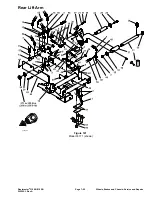

g214673

Figure 163

1.

Bedbar adjuster screw

3.

Bedbar

2.

Spring tension locknut

4.

Shoulder bolt

4. Loosen, but do not remove, the three (3) shoulder bolts that secure the side

plate to the frame opposite the side that is not level (

5. Adjust the position of the side plate to parallel the rear roller and cutting reel.

Then, tighten the shoulder bolts to a torque from

37 to 44 N-m (27 to 33 ft-lb)

.

6. After tightening the side plate, recheck the rear roller. If necessary, loosen

and adjust second side plate.

DPA Cutting Units: Adjustments

Page 8–4

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......