10

BATTERIES DISPOSAL

It is compulsory to hand over exhausted bat-

teries, classified as dangerous waste, to an

authorized institution according to the current

laws.

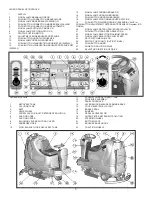

CONNECTION BATTERIES' CONNECTOR

AND SWITCHING ON OF THE MACHINE

Once that the battery recharging has been

completed:

1. Disconnect the connector of the battery

recharger from the battery connector (1).

2. Connect then the battery connector (1) to

the machine connector (2).

BATTERIES CHARGE LEVEL INDICATOR

To start any function of the machine, it is

necessary to rotate clockwise the key

switch (24). Rotating it counterclockwise

any function will be switched off.

WHEN THE MACHINE IS SWITCHED ON,

ON THE DISPLAY (1) APPEAR IN ORDER

THE FOLLOWING INFORMATION:

1. the version (for example A003) of software

installed on the machine.

2. the setting of the battery check card which

can be: GE 24 (check card set for GEL

batteries).or Pb 24 (check card set for lead

batteries).

3. The batteries charge level indicator is digital and

remains fixed on the display. The battery charge level

starts from 100, which indicates the 100% of the total

charge and decreases from 100 to 10. When the charge

level reaches 20%, the display starts blinking, so you

are about the end of working.

After few seconds of the indication 10% and

after this, the blinking of the four lines, all the functions

stop automatically. With the remaining charge it is any-

how possible to finish the drying operation before

proceeding to the recharge.

SETTING OF THE BATTERY CHECK CARD

The setting of the battery check card can be:

GE 24 (check card set for GEL batteries).

or

Pb 24 (check card set for lead batteries).

The machine, if not specified otherwise, is supplied

with the battery check card set for lead batteries. To

modify this setting, it is necessary to:

1. Switch off and on the machine.

2. Immediately after having switched on, when on the

display (1) the writing Pb24 appears, press simultane-

ously the push buttons (3) and (6) up to the blinking of

the writing.

3. When the writing begins to blink, take off the fingers

from the push buttons and press once the push button

(6).

4. The writing GE24 appears blinking.

5. When the writing stops to blink, the setting is modi-

fied.

For the passage of the setting from gel batteries into

lead batteries, repeat the procedure pressing

button (3) instead of button (6).

HOUR METER

The machine is equipped with an hour meter located

on the same display (1) of the battery charge level

indicator. Keeping the button (13) pressed, the first data

indicates the

working hours and after a few seconds the work-

ing minutes are shown.

SQUEEGEE ASSEMBLY

1. Maintain the squeegee support (1) slightly lifted

from the floor.

2. Insert the threaded parts of the two knobs (4)

making them slide inside the two slots on the sup-

port placed on the upper part of the squeegee (2).

3. Put the washers (3) into position, they are two

for each knob, so that they are assembled one

under and the other on each of the two slots pres-

ent on the support.

4. Block the squeegee by rotating the two knobs

(4) clockwise.

5. Insert the squeegee hose (5) into its coupling,

respecting its position as indicated in the figure.

ADJUSTMENT OF THE SQUEEGEE

In order to have a perfect drying result through

the squeegee, the rear rubber must have the

lower bending uniformly adjusted in all its length.

For the adjustment, it is necessary to put oneself

in working condition and therefore the suction mo-

tor has to be switched on and the brushes have to

function together with the detergent solution.

The lower part of the rubber is too much bent

Take off the pressure rotating the wing nut (6)

counterclockwise.

The lower part of the rubber is not much bent

Increase the pressure rotating the wing nut (6)

clockwise. Check that the wheels which adjust the

height do not rest on the floor, in this case adjust

them as indicated in paragraph “Height adjust-

ment”.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...