NIRE-170-1-6

41

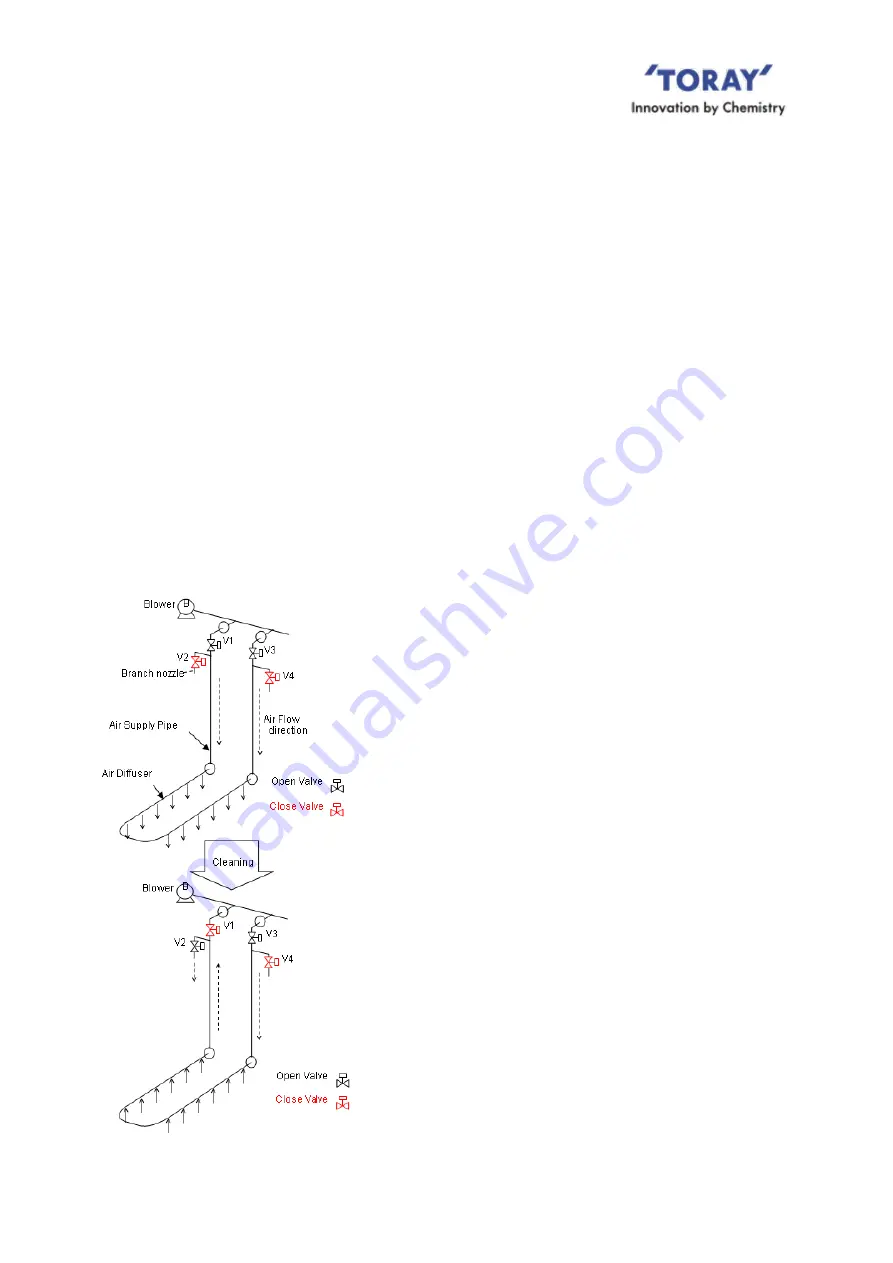

2. Air Diffuser Cleaning

A clogged air diffuser cannot evenly distribute air to the membrane elements resulting in

solids build up on the membrane element surface or, in extreme cases, membrane element

damage.

It is recommended that that the MBR module(s) be fitted with air diffuser

cleaning components/valves that can be automatically controlled from the MBR

system PLC. Cleaning of the air diffusers should be performed, at a minimum, once

per 24 hour period or as needed to maintain even air distribution.

To clean the air

diffuser holes it is necessary to draw flow from the activated sludge through the diffuser holes

into the diffuser piping and finally out the air/sludge discharge nozzles. This is accomplished

by supplying air to the diffuser piping by different way (see below). The flow of air through the

diffuser and out the discharge nozzle will create a suction drawing sludge into the diffuser

piping. It is this reverse flow of sludge that will remove any accumulated solids trapped in the

diffuser holes. Following the same procedure, but reversing the air flow direction through the

diffuser piping, will further improve the efficiency of the air diffuser cleaning.

When performing an air diffuser cleaning cycle, observe the flow coming out of the discharge

nozzles (V2 and V4). In some cases lengthening the duration of the diffuser cleaning cycle

can improve the efficiency of the diffuser cleaning cycle.

(1)

Air diffuser cleaning procedure - Principle

(i)

Stop the filtration process.

(ii)

Open V2 discharge nozzle valve.

(iii)

Close V1 valve. These valve settings will result

in liquid sludge flowing through the diffuser

holes, into diffuser piping, and the mix of air and

sludge will be discharged through V2.

(iv) Keep V2 valve open for 1 to 5 minutes.

(v)

Open V1 valve, and then close V2 valve.

(vi) Clean the other line in the same manner as

follows.

(vii) Open V4 discharge nozzle valve.

(viii) Close V3 valve. These valve settings will result

in liquid sludge flowing through the diffuser

holes, into diffuser piping, and the mix of air and

sludge will be discharged through V4.

(ix) Keep V4 valve open for 1 to 5 minutes.

(x)

Open V3 valve, and then close V4 valve.

(xi) Restart the filtration process.