30

INSTALLATION AND USE INSTRUCTIONS

EN

V1

4.6

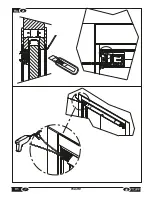

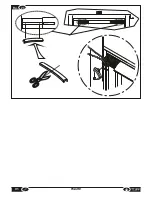

INTERNAL SENSOR DETECTION AREA ADJUSTMENT

It is possible to adjust the automation's internal sensor detection area by covering the detect window with one ( or more

toghether ) of the covering masks contained in the package

(Fig.24)

.

If the sensor's detection area is too far away from the door, use a label type 'b-c';

If the sensor's detection area is too broad at the sides of the door, use a label type 'd-e-f';

If the detection area is too broad in both directions, use label 'a' or several labels together.

4.5

RESET PROCEDURE

The reset procedure can be used to restore normal door operation following any alarms that caused the system to go into

block mode.

WARNING: During the procedure do not disconnect the power, do not open or close the door manually and do

not touch any of the keys on the electronic board.

WARNING

:

During the initialization and reset procedures all controls (sensors, remote controls, etc.) are

blocked. Therefore, stand clear of the door operating area.

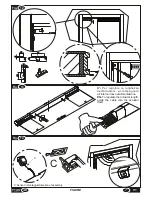

Access the automation unit's electronic circuit board as shown in

fig.20.

-

Figure 22:

This procedure can be initiated by holding down button S1 for 2 seconds or by pressing reset button 7 on the

remote control. On receiving the command, the door will open very slowly and then close again at the normal set speed.

Once closed the door will go into standby mode, restoring normal operation. The door open time during the reset cycle is

much longer than in a normal cycle.

Default settings provide for very slow opening / closing speed and for automatic reset in the event of lack of

supply voltage. For more details see Section 4.3.

Note: the Pull&go function becomes active once again 5 seconds after the reset procedure is completed.

.

After the reset procedure, close the sliding cover on the board.

4.7

TIMER MODE OPENING AND CLOSING FUNCTION

CAUTION: to use this function it is necessary to have a TS8 remote control, EB1 electric lock and two Hs2

touch controls.

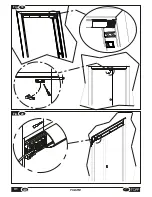

To activate the timer mode function, extract the internal sensor, remove the connector then insert it back into its housing,

while making sure that the flat sensor cables are neatly arranged inside the actuator.

Mount the two HS2 touch controls, one inside and the other outside the room. Lastly, connect the cables of the two touch

controls as follows:

Ÿ

HS2 inside room:

terminal E

in Fig.

22.

Ÿ

HS2 outside room:

terminal D

in

Fig. 22.

Next, shift

dip switches 6

and

7

to

ON

and run a reset procedure as described in

Par 4.5.

After 24 seconds from the end

of the reset, electric lock EB1 will activate to lock the door.

The timer mode function allows for unlocking the door by means of a command

activated through the first button on the TS8 remote control. At this point, the

EB1 electric lock will deactivate and the green light will appear in the HS2 touch

controls. This mode will remain active for 24 seconds before the door locks again.

while the electric lock is deactivated, the door can be opened by touching the

HS2 touch control. Once the door closes, the electric lock will reactivate and

prevent opening of the door from the outside (HS2 with red light). To exit from

inside the door, simply touch the internal HS2 touch control and the door will

open. Once the door closes again, it will return to its initial status with the electric

lock activated.

If the door is unlocked while a person is inside the room, he/she can touch the

HS2 touch control to re-lock the door and subsequently touch the control again

to unlock and open the door. Lastly, if – with the door open – the HS2 touch

Control is kept pressed, the door will remain open and will close once the button

is released.

Moreover, the above function can be enabled or disabled through the Ts8

remote control. To activate and deactivate the «timer mode opening and closing

function», press the fifth function (third button) on the TS8 remote control.

HS2 outside room

HS2 inside room

Summary of Contents for V1

Page 2: ...2 ISTRUZIONI PER L INSTALLAZIONE E L USO IT V1 ...

Page 35: ...IT 7 FIGURE Fig 6 misura measurement X Fig 7 2cm 35 V1 FIGURE max 250mm A ...

Page 36: ...Fig 9 Fig 8 250mm 12mm 12mm 36 FIGURE V1 ...

Page 40: ...10 Fig 20 Fig 19 V1 FIGURE 40 ...

Page 41: ...Fig 21 41 V1 FIGURE ...

Page 43: ...Fig 23 TOPP V1 TOPP V1 43 V1 FIGURE ...

Page 44: ...Fig 24 a b c d e f V1 FIGURE 40 44 ...

Page 45: ... 45 V1 FIGURE ...

Page 46: ... V1 FIGURE 40 46 ...

Page 47: ......