MAINTENANCE AND TROUBLESHOOTING

30

If there is any problem and has no the authorized professional maintenance personal, please

contact local agent or the branch company!

If there are some simple troubles of TIG200E AC/DC -series welding machine, you can consult the

following overhauling chart:

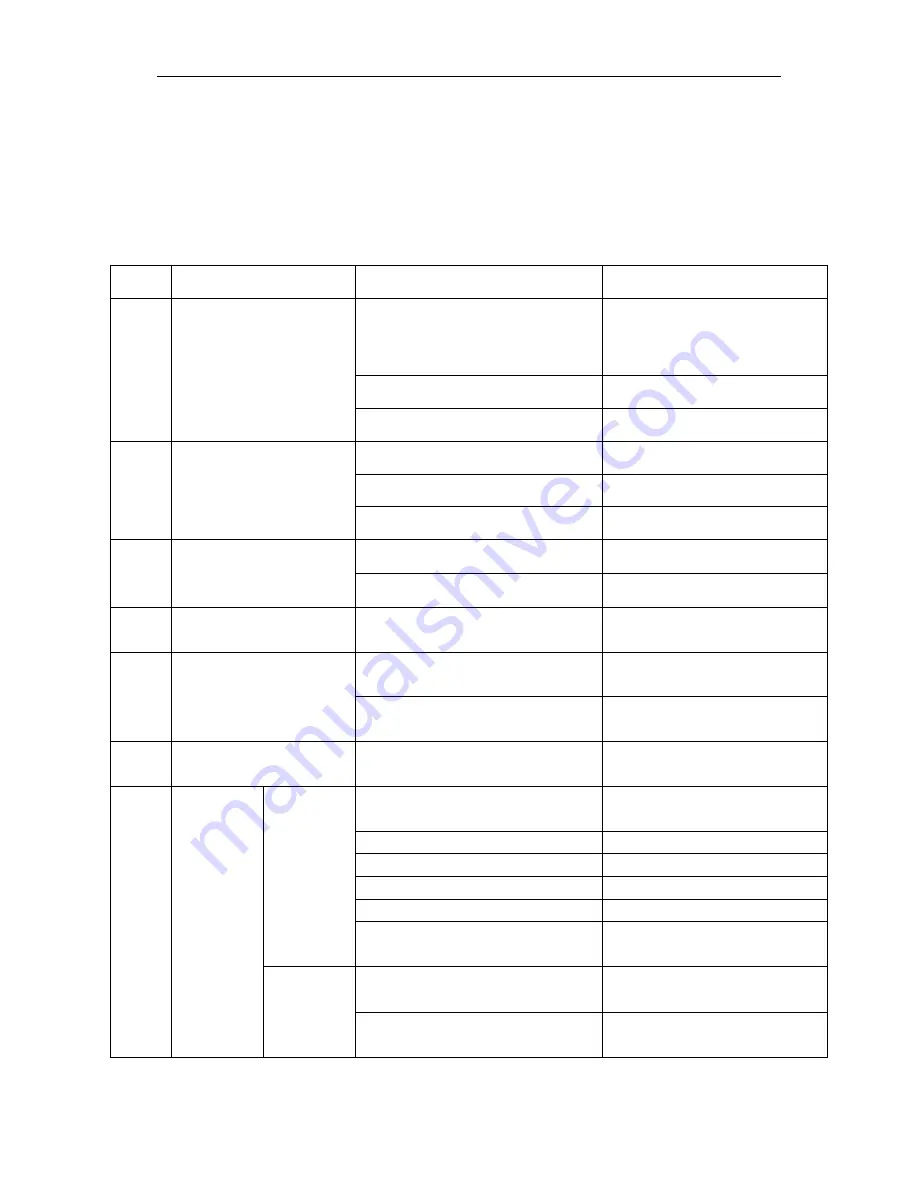

S/N

Troubles

Reasons

Solution

1

Turn on the power source, and

fan works, but the power pilot

lamp is not on.

The power light damaged or connection is

not good

Check and repair Pr7

The transformer of power is broken

Repair or change the transformer

Control PCB failures

Repair or change the control Pr4

2

Turn on the power source, and

the power lamp is on, but fan

doesn’t work

There is something in the fan

Clear out

The start capacitor of fan damaged

Change capacitor

The fan motor damaged

Change fan

3

Turn on the power source, the

power lamp is not on, and fan

doesn’t work

No power supply input

Check whether there is power supply

The fuse inside the machine damaged

Change it (3A)

4

The number on the display is not

intact.

The LED in the display is broken

Change the LED

5

The max and min value

displayed doesn’t accord with

the set value.

The max value is not accordant (refer to

§3.1)

Adjust potentiometer Imin on the power

board.

The min value is not accordant (refer to

§3.1)

Adjust potentiometer Imaxin the current

meter.

6

No no-load voltage output

(MMA)

The machine is damaged

Check the main circuit and the Pr4.

7

Arc can not be

ignited (TIG)

There is spark

on the HF

igniting board.

The welding cable is not connected with the

two output of the welder.

Connect the welding cable to the

welder’s output.

The welding cable damaged.

Repair or change it.

The earth cable connected unstably.

Check the earth cable.

The welding cable is too long.

Use an appropriate welding cable.

There is oil or dust on the workpiece.

Check and remove it.

The distance between tungsten electrode and

workpiece is too long.

Reduce the distance (about 3mm).

There is not

spark on the

HF igniting

board.

The HF igniting board does not work.

Repair or change Pr8

The distance between the discharger is too

short.

Adjust this distance (about 0.7mm).