Page 13

1

3

TROUBLESHOOTING

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Motor will not start.

1. Low voltage

2. Open circuit in motor or loose

connections.

3.

4.

Blown fuse or breaker.

Low temperature

1. Start the motor at high speed.

2. Inspect all lead connections on motor

for loose or open connections. (Send

for Servicing.)

3. Short circuit. (Send for Servicing.)

4. Improper match between tool and

circuit, fuse or breaker.

Motor will not start – fuses

or circuit breakers tripping

or blowing.

1. Short circuit in line, cord or

plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit break-

ers in power line.

1. Inspect cord or plug for damaged in-

sulation and shorted wires.

2. Inspect all connections on motor for

loose or shorted terminals and/or worn

insulation.

3. Install correct fuses or circuit breakers

or switch tool to an appropriately sized

circuit.

Motor overheats.

4. Motor is overloaded.

5. Extension cord is too long and

6. Poor air circulation around the

motor

4. Reduce load on motor (pressure on

the sandpaper from the object being

sanded.)

5. Utilize an extension cord of appropriate

gauge and length or plug tool directly

into outlet.

6. Reduce the motor run time.

Motor stalls or runs slow -

resulting in blown fuses or

tripped circuit.

1. Motor is overloaded.

2. Short circuit in the motor or

loose connections.

3. Low line voltage.

4. Incorrect fuses or circuit break-

ers in the power line.

5. Motor capacitor has failed.

6. Belt tension is too tight.

1. Reduce the load on the motor.

2. Inspect connections on motor for loose

or shorted terminals or worn insulation.

3. Correct low voltage conditions (for ex-

ample: improper extension cord length

and/or wire gauge).

4. Install

CORRECT

fuses or circuit

breakers or plug tool into an appropri-

ate circuit, matched to an appropriate

fuse or breaker.

5. Replace motor capacitor.

6. Decrease belt tension.

Machine slows down when

operating.

1. Feed rate is too great.

2. Undersized circuit or use of

undersized extension cord.

1. Reduce the rate at which the work is

fed into the sandpaper.

2. Ensure circuit wires or extension cords

are proper gauge, or eliminate use of

extension cords.

Machine vibrates

excessively or makes

excess noise.

1. Incorrect motor mounting.

2. Incorrect sanding-belt tension.

3. Weak or broken belt tension

spring.

4. Idler roller is too loose.

5. Broken/defective sanding belt

or disc.

6. Drive belt is too tight

1. Make sure all fasteners are tightened.

2. Adjust tension-adjustment knob.

Follow belt tensioning/tracking instruc-

tions in this manual.

3. Replace belt tension spring by service

technician.

4. Have service technician adjust idler

roller.

5. Replace sanding belt/disc.

6. Decrease belt tension.

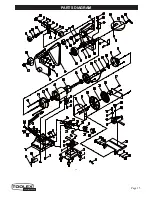

Summary of Contents for 598557

Page 15: ...Page 15 PARTS DIAGRAM 15 ...