4.1 After the truck is assembled, try to rock the hand grip and operate different positions of

control handle knob 40 to examine the lifting, free position and dropping and check that

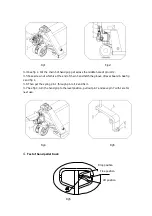

whether the different positions are normal or not. See fig 5.

4.2 The screw 9 in fig 4 is used to adjust the truck situation. When the truck body drops

immediately after it is lifted, you should turn the screw 9 a little counter-clockwise.

And then try the truck again until truck body could lift normally. If the truck body couldn’t

drop after it is lifted, you should turn the screw 9 a little clockwise. And then try to operate

truck again until the truck body could drop normally. The external hexagon nut 8 at screw

9

Plays the locking function in the truck. So you should undo the external hexagon nut 10 before

adjustment. And screw down the nut 10 after you finish the adjustment.

。

5. Operation instruction

5.1 Before operation of the hand pallet truck please make sure that whether the cargo weight

exceeds the rated load or not.

5.2 The cargo loading type is shown as fig 6

5.3

See fig 5, when hand knob 40 is placed on the lift position, the truck will be in a state of lift.

At this time, if you rock the hand grip, the truck will be lifted.

。

5.4 See fig 5, when hand knob 40 is placed on the free position, the truck will travel. At this time,

if you rock the hand grip, the truck will neither lift nor drop. Then, you can use the truck to

move the cargo.

5.5 See fig 5, when the hand knob 40 is placed on

The drop position, truck forks will drop. At this time, the truck forks will drop automatically.

5.6 Should make the pallet off ground when weighting

fig 6

Chart 8

Summary of Contents for 596365

Page 1: ......