CAUTION: Air tools hazard

WWW.TMGINDUSTRIAL.COM

P16/27

Toll Free:1-877-761-2819

3.

Starting engine. (See the engine manual

for more details.)

a.

Move fuel valve lever to the ON position.

b.

For a cold engine, move choke lever to

the CLOSED position. For a warm

engine, leave in OPEN position.

c.

Turn engine switch to ON position.

d.

Grab the recoil starter grip and rapidly

pull out the starter cord. Allow starter

cord to return slowly.

4.

When engine starts, gradually move choke

lever to OPEN position.

5.

After engine has started, move the

unloader to the engine RUN position.

6.

The compressor is now ready to use.

7.

The unloader will maintain pressure in the

tank between 145 to 175 PSI.

8.

Under long, continuous-run

operating conditions, be

prepared to:

Check and refuel on a regular basis.

See engine Owner’s Manual for

more detail.

Check engine oil level each time you

refuel.

NEVER

over-pressurize the receiver tank or air tools

beyond nameplate capacity. Do not operate the unit at

pressures, temperatures or rotational speeds in

excess of manufacturer’s recommendations. Be sure

all accessory equipment and system components

meets or exceeds the pressures and temperatures

developed by the unit. Exceeding the pressure rating

could cause them to explode or fly apar

t.

WARNING

Compressor and any tools must be sized

properly- consider the maximum pressure

requirements and air volume of each.

(Maximum operating pressure of your

compressor and volume rating is listed in

“

Specifications

” section of this manual.)

Inspect hoses for holes or rupture points.

Ensure the switch is in the OFF position and

tank pressure gauge reads zero before

changing air tools or disconnecting hose

from air outlet. Failure to do so could result

in personal injury

.

NEVER use air tools or attachments

without first determining the maximum

pressure recommended for that equipment.

WARNING: Overheating

Do not operate this unit with any components

rated less than the maximum operating

pressure of the unit (175 PSI) unless a

regulator limiting pressure is used.

Note: Many tools are rated for only 90 PSI. It is

acceptable to use a tool rated for 90 PSI when

max. pressure of compressor is 175 ONLY if a

regulator is used and the regulated pressure is

90 PSI or less.

When using high-pressure tools, make sure

the tool is properly coupled, user is wearing

protective equipment, and there are no

persons nearby.

Attaching Air Hose and Tools

Air Hose and Tool Use

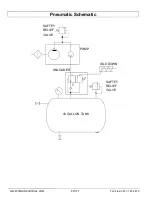

Pressure control related devices.

Never remove,

adjust, bypass, change, modify or make

substitutions for safety/relief valves, pressure

switches or other pressure control related devices.

Over-pressurization of the compressor could

result and cause explosion.

1.

Connect air hose to ball valve outlet.

2.

Connect tool to other end of the hose.

3.

Keep fingers off trigger of tool until ready

to use. A tool has power when compressor

has air.

4.

Ensure connections are tight/secure. Firmly

grasp hose in hand when connecting or

disconnecting to prevent hose whip. An

improperly seated coupler can blow off the

machine when started.

This compressor is not equipped with “auto shut

off”. Do not allow to overheat. Failure to allow

adequate ventilation or restrict the air flow may

cause the machine to overheat.

Never use compressor to inflate small low-

pressure objects, i.e., balloons/inflatables, small

or low volume PSI tires. It is easy to over-

pressurize them, causing them to rupture. Use a

gauge to check the pressure regularly. Observe

the inflation capacity of

the object prior to

filling with air.

CAUTION: Incompatable

component hazard

WARNING: Inflatables/Low PSI tire

WARNING: Bursting hazard

Do not attach air tools to open end of the hose until

start-up is completed and the unit checks

out OK.

Too much air pressure causes a hazardous risk of

bursting. Check the manufacturer’s maximum

pressure rating for air tools and accessories. The

outlet pressure must never exceed the maximum

pressure rating.