172-65563MAJ-03 (P46S) 6 Oct 2021

6

Operation

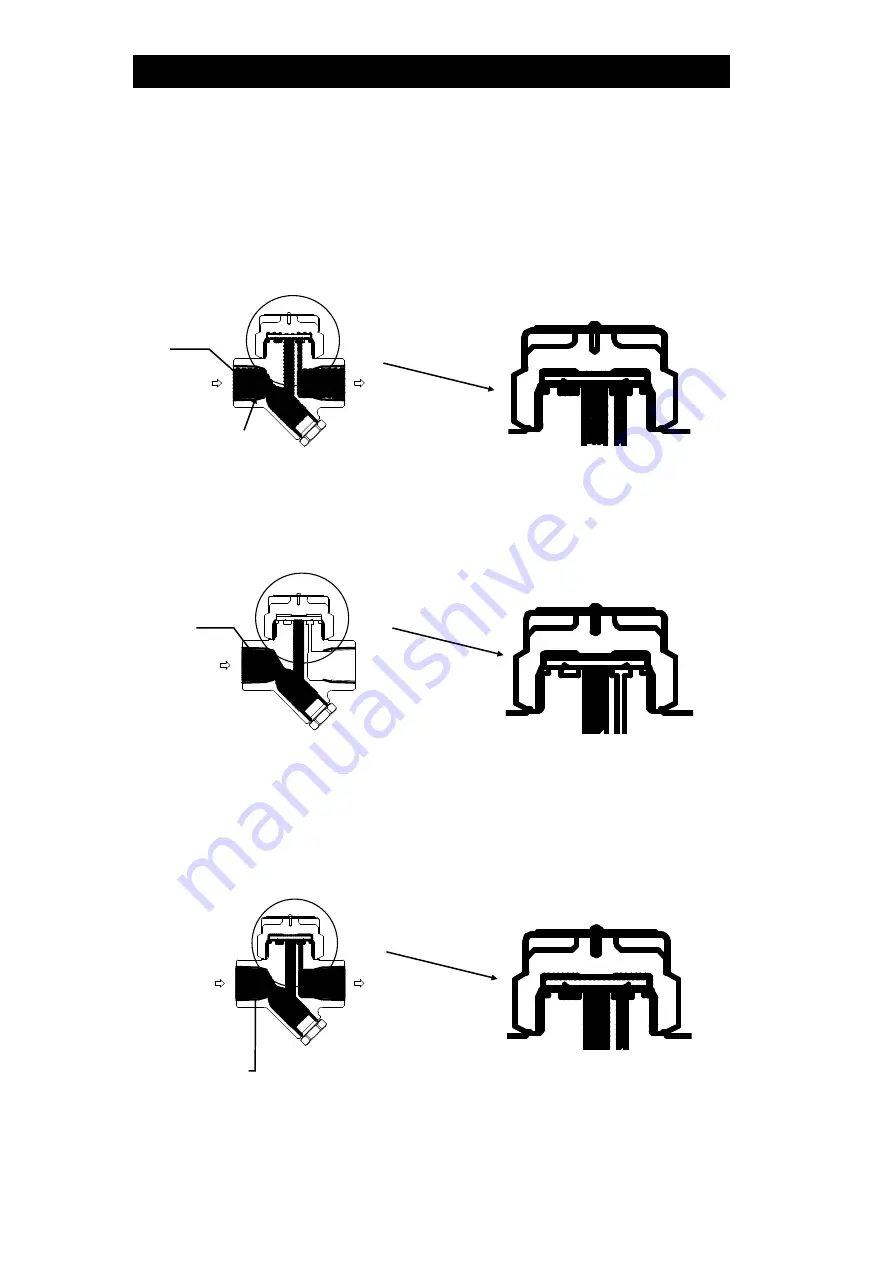

Principle of Air and Condensate Discharge

1. Start-up: Discharge of Initial Air and Cold Condensate

At start-up, the flow of large quantities of initial air and cold condensate lift the

disc off the seat, thus opening the valve. This allows for the rapid discharge of

initial air and cold condensate.

2. Steam Enters, Valve Closes

The rapid influx of steam creates a low-pressure region under the disc, which

suctions it onto the seat. The pressure chamber above the disc becomes a

high-pressure region when entering steam is compressed. This difference in the

pressures above and below the disc gives the closed valve a tight seal.

3. Condensate Discharge

When condensate enters the trap, the temperature in the pressure chamber

drops, causing the steam to condense and the pressure to drop. The inlet

pressure, which is now greater than the pressure pushing down on the disc,

opens the valve, thus allowing condensate to be discharged. When steam

again enters the trap, the valve closes, as in step 2. In this manner, condensate

is automatically and intermittently discharged as the valve opens and closes.

Air

Cold Condensate

Steam

Condensate