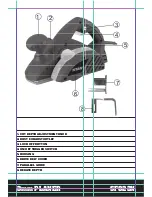

V-groove

Fig 5

your planer show signs of becoming dull, replace

them.

Caution:

Always use two hands on the tool for

any operation, this assures you maintain control

and avoid the risk of serious personal injury.

Workpiece must always be properly supported

and clamped so both hands will be free to control

the planer.

4. CHAMFERING

(see fig5 and fig6)

The planer has been designed with chamfering

grooves in the front base plate. The purpose for

this groove is chamfering edges of boards.

Before making a cut on good timber, practice

cutting on scrap timber to determine the amount

to be removed. Clamp the work piece so it will

not move during this operation. Firmly holding

the cut depth adjustment knob with your left

hand and the rear handle with your right hand,

place the chamfering groove on the surface to be

cut. Start your planer and let it reach full speed,

then slowly move it into the work piece. Maintain

downward pressure to keep your planer flat at

the beginning and the end of the work surface.

5. USING THE PARALLEL GUIDE

(see fig7)

Insert the screw provided through the hole on the

support of parallel guide. Then turn the screw into

the nut on the housing. Fix the parallel guide on

the support of parallel guide with the screw and

nut. Ensure the screws are tightened securely.

Note:

The parallel guide should be fitted on left

of housing (see fig7).

To adjust the parallel guide to required width of

cut, loosen the nut and slide the parallel guide to

the required position. Retighten the nut fully.

When making cuts using your parallel guide, the

guide should be held firmly against the edge of

the workpiece.

6. USING THE DEPTH GUIDE

(see fig8)

Insert the screw provided through the slot on the

depth guide. Then turn the screw into the nut on

the housing.

The cut depth adjustment can be set from 0mm

to 18mm.

To adjust the depth guide to depth of cut, place

the planer on a flat board, then loosen the screw

and slide the cut depth adjustment guide up and

down for required depth, then tighten the thumb

Fig 6

Screw

Parallel guide

Support of

parallel guide

Fig 7

Screw

Depth guide

Fig 8