TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

7/21

10

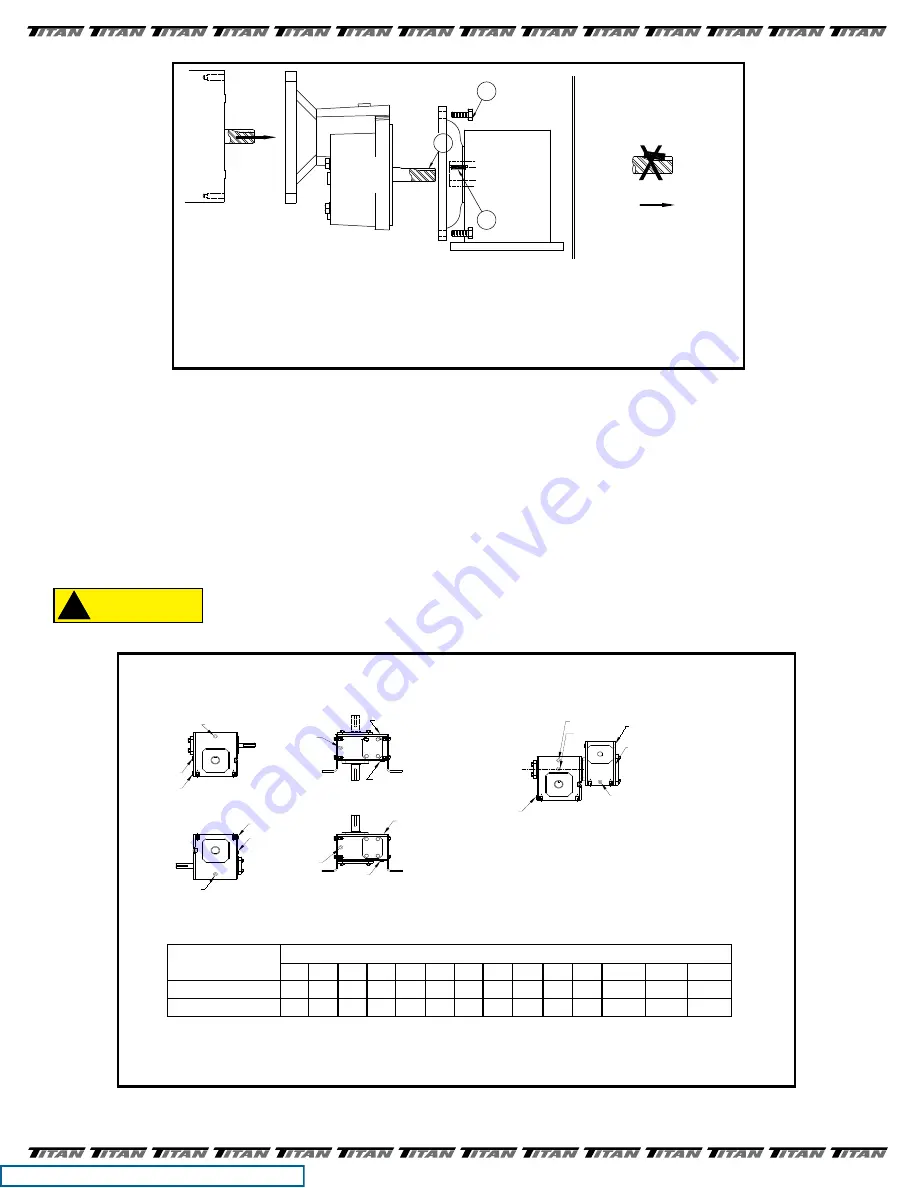

2. VENTILATION

- During normal operation gear reducers build up heat and pressure that

MUST

be vented to protect

the seals and gears. If not installed at Titan, a brass vent plug contained in a small plastic bag, will be put in a box

or larger bag along with fasteners sent loose for use during field installation. Remove thetop most drain plug (refer

to

FIGURE 6

for the position of your reducer) and install the vent plug securely in place.

3. CLEANING - After approximately two to three weeks of operation the reducer

MUST

be drained, flushed out, and

refilled to the proper level with fresh oil. (This is done to remove brass particles caused during thenormal wear-in

period of the worm gear.) Afterwards, the oil should be changed in your reducer every 2500 hours or every

6 months, which ever occurs first.

Where high temperatures and/or dirty atmosphere exists more frequent changes

may be necessary. Periodically check reducer to ensure that the proper level of

oil is in the reducer. Too little oil will cause accelerated wear on the gears. Too

much oil can cause overheating, seal deterioration, and leakage.

FIGURE 5

CAUTION

!

SIDEMILL

MOTOR

SHAFT

BORE

REDUCER

KEYSEAT

CUT

MOTOR

SHAFT

1

3

NO!

IF MOTOR SHAFT HAS A KEYSEAT MADE BY AN ENDMILL NO SPECIAL ASSEMBLY STEPS ARE REQUIRED.

THE CORRECT ASSEMBLY PROCEDURE IS TO PLACE THE KEY INTO THE REDUCER KEYWAY.

THEN LINE UP MOTOR KEYSEAT WITH KEY IN REDUCER. PUSH MOTOR SHAFT ONTO REDUCER

AND BOLT TOGETHER.

MANY OF TODAY'S MOTORS HAVE KEYSEATS

CUT WITH A SIDEMILL CUTTER. IF YOU

PLACE THE KEY IN THE MOTOR KEYSEAT

IT CAN SLIDE BACK AS THE MOTOR SHAFT

IS PUSHED INTO THE HOLLOW INPUT SHAFT

OF THE REDUCER. THIS CAN CAUSE THE

HOLLOW INPUT SHAFT TO BREAKOUT

RUINING THE SEALS, ALLOWING OIL LEAKAGE,

AND FURTHER DAMAGE.

NOTE: IT IS ALSO ADVISABLE TO APPLY FEL-PRO C5A ANTISEIZE OR MOBILETEMP 78 GREASE TO THE

BORE OF THE REDUCER THIS WILL MAKE ANY FUTURE DISASSEMBLY MUCH EASIER..

2

RATIO

MULTIPIER

Mounting

Position

UNIT SIZE

813 815 818 821 824 826 830 832 842 852 860

870*

880*

8100*

1 - Worm Over

4

12

12

20

24

40

56

72

112 188 312

35

48

72

2 - Worm Under

8

16

20

28

40

60

84 108 152 304 328 32-3/4 51-1/4

80

Oil Capacities (ounces) - Standard Units

16 0z. = 1 pint

2 pints = 1 quart

4 quarts = 1 gallon

1 gallon = 128 oz. = 231 Cu. in.

DRAIN

LEVEL

VENT

WORM OVER

VENT

LEVEL

DRAIN

VERTICAL OUTPUT

VENT

LEVEL

DRAIN

WORM UNDER

VENT

LEVEL

DRAIN

VERTICAL INPUT

LEVEL*

VENT

DRAIN

VENT

LEVEL

DRAIN

DOUBLE REDUCTION WORM-WORM

(All primary units have

their own oil level)

* Size 842-860 (far side plug)

Note: High oil level applies to all size 842 & larger

secondary & tertiary units regardless of primary

unit type.

Standard Gear Reducer Mounting Positions

& Vent Plug, Level and Drain Locations

FIGURE 6

Go to Table of Contents