Performance Series 450e

9

GB

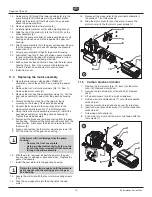

Spraying Technique

1

2

4

5

3

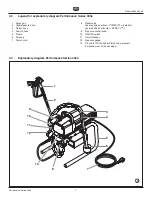

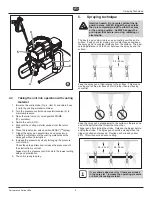

4.4 Taking the unit into operation with coating

material

1. Immerse the suction tube (Fig. 4, Item 2) and return hose

(1) into the coating material container.

2. Turn the pressure control knob counterclockwise (3) to

minimum pressure.

3. Open the relief valve (4), valve position PRIME

(

k

circulation).

4. Switch the unit (5) ON.

5. Wait until the coating material exudes from the return

hose.

6. Close the relief valve, valve position SPRAY (

p

spray).

7. Trigger the spray gun several times and spray into a

collecting container until the coating material exits the

spray gun without interruption.

8. Increase the pressure by slowly turning up the pressure

control knob.

Check the spray pattern and increase the pressure until

the atomization is correct.

Always turn the pressure control knob to the lowest setting

with good atomization.

9. The unit is ready to spray.

5.

Spraying technique

Injection hazard. Do not spray without the tip

guard in place. NeVeR trigger the gun unless

the tip is completely turned to either the spray

or the unclog position. ALWAyS engage the

gun trigger lock before removing, replacing or

cleaning tip.

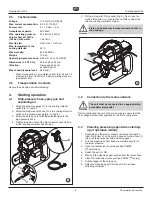

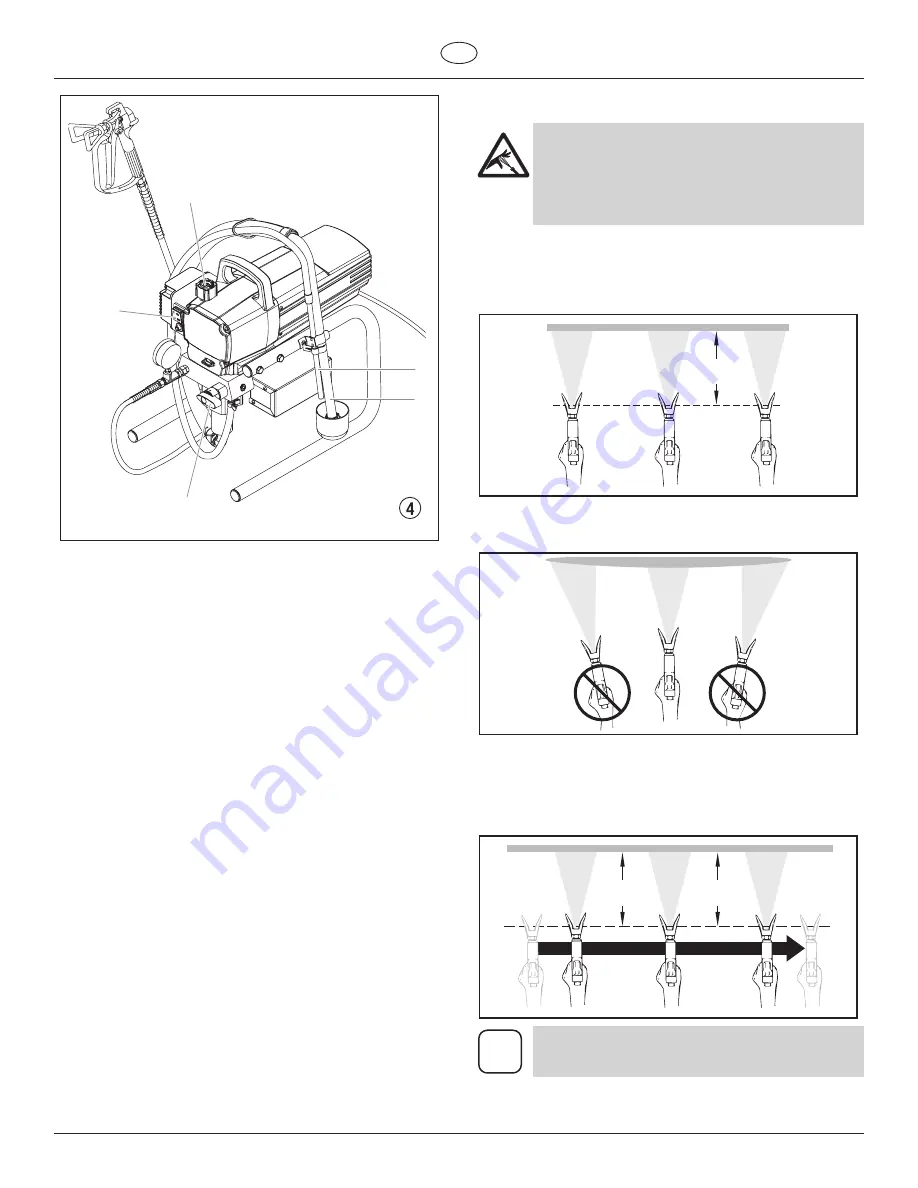

The key to a good paint job is an even coating over the entire

surface. Keep your arm moving at a constant speed and keep

the spray gun at a constant distance from the surface. The best

spraying distance is 25 to 30 cm between the spray tip and the

surface.

25 - 30 cm

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Keep the spray gun perpendicular to the surface, otherwise one

end of the pattern will be thicker than the other.

Trigger gun after starting the stroke. Release the trigger before

ending the stroke. The spray gun should be moving when the

trigger is pulled and released. Overlap each stroke by about

30%. This will ensure an even coating.

25 - 30 cm

25 - 30 cm

i

If very sharp edges result or if there are streaks

in the spray jet – increase the operating pressure

or dilute the coating material.