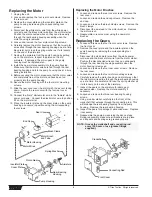

Replacing the Motor

1. Unplug the unit.

2. Loosen and remove the four rear cover screws. Remove

the rear cover.

3. Remove the cover plate and the insulator plate on the

pump housing by removing the corresponding four

screws.

4. Disconnect the white motor wire from the white power

cord wire and the black motor wire from the motor starter.

Position the disconnected wires so they can slide easily

through the rear bearing housing assembly when the

motor housing is removed.

5. Loosen and remove the four motor mounting screws.

6. Carefully remove the motor housing so that the two motor

wires slide through the rear bearing housing one at a time.

Be careful not to lose the spring washer as it sits loosely

on the end of the armature.

7. Remove the armature from the pump housing by pulling

up on the armature. Inspect the pinion on the old

armature. If damaged, the pinion gear in the pump

housing must be replaced also.

8. Install the new motor assembly into the pump housing.

Make sure that the motor wires are fed through the rear

bearing housing and into the pump housing one at a time

during installation.

9. Before securing the motor, make sure that the motor wires

are completely free of the motor and have been fed

properly into the pump housing.

10. Secure the motor housing with the four motor mounting

screws.

11. Slide the rear cover over the motor with the air vent facing

down. Secure the rear cover with the four rear cover

screws.

12. Connect the “male” white motor wire to the “female” white

power cord wire. Connect the black motor wire to position

#2 on the motor starter.

13. Place the insulator plate and the cover plate on the pump

housing and secure in position using the corresponding

four screws.

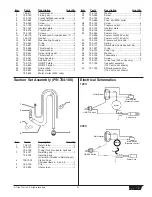

Rear Cover

Insulator Plate

Motor Housing

End Cap

Motor Brush

and Tube

Pinion Gear

Spring Washer

Cover Plate

Brush Clamp

Rear Bearing

Housing

Pump Housing

Armature

Motor Wires

8

© Titan Tool Inc. All rights reserved.

Replacing the Motor Brushes

1. Loosen and remove the rear cover screws. Remove the

rear cover.

2. Loosen and remove the end cap screws. Remove the

end cap.

3. Loosen and remove the brush clamp screws. Remove the

brush clamps.

4. Disconnect the wire lead to the motor brushes. Remove

the motor brush.

5. Reassemble in reverse order using the new motor

brushes.

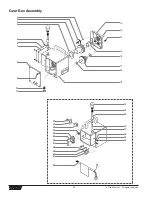

Replacing the Gears

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Remove the cover plate and the insulator plate on the

pump housing by removing the corresponding four

screws.

3. Disconnect the white motor wire from the white power

cord wire and the black motor wire from the motor starter.

Position the disconnected wires so they can slide easily

through the rear bearing housing assembly when the

motor housing is removed.

4. Loosen and remove the four rear cover screws. Remove

the rear cover.

5. Loosen and remove the four motor mounting screws.

6. Carefully remove the motor housing and armature so that

the two motor wires slide through the rear bearing housing

one at a time. Be careful not to lose the spring washer as

it sits loosely on the end of the armature.

7. Inspect the gears on the armature for damage or

excessive wear. Replace the motor assembly if

necessary.

8. Loosen and remove the three rear bearing housing

screws.

9. Using a rubber mallet, carefully tap the front of the

crankshaft that extends through the connecting rod. This

will dislodge the rear bearing housing from the pump

housing. Remove the rear bearing housing.

10. Inspect the gears for damage or excessive wear. Replace

if necessary.

11. Reassemble the pump by reversing the above steps.

During reassembly, make sure all washers are in place

and all gears and bearings are greased properly.

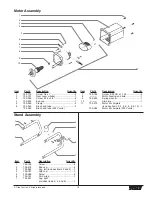

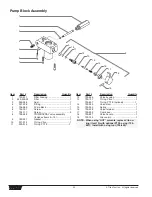

Crankshaft

Connecting Rod

Front Cover

NOTE: Grease the crankshaft and connecting rod

every 100 hours of use (grease fittings

supplied).