OPERATING INSTRUCTIONS

TM-CHAIN BLOCKS

B07725-G

EN 06.2022

8 | 12

Take chain blocks out of service immediately in the event of the following defects:

•

illegible or missing markings

•

deformation, stretching or breakage of chains or components

•

cuts, notches, cracks, tears, crushes

•

heating above the permissible temperature range

•

severe corrosion

•

missing or defective safety devices

6.2

Normal use

Observe for damage or unusual noises that indicate a potential problem. Do not operate a chain

block if the load chain cannot move freely. Check for clicking noises, jamming or incorrect

operation. The clicking sound of the pawls on the ratchet wheel during lifting is normal.

If the load chain jams, jumps or makes excessive noise, inspect it.

Also make sure that the hand chain can move freely, is not jammed and has no damage.

If problems continue, send the chain block to the service address for inspection or repair.

Do not put chain blocks into operation until all defects have been eliminated.

6.3

Load chain

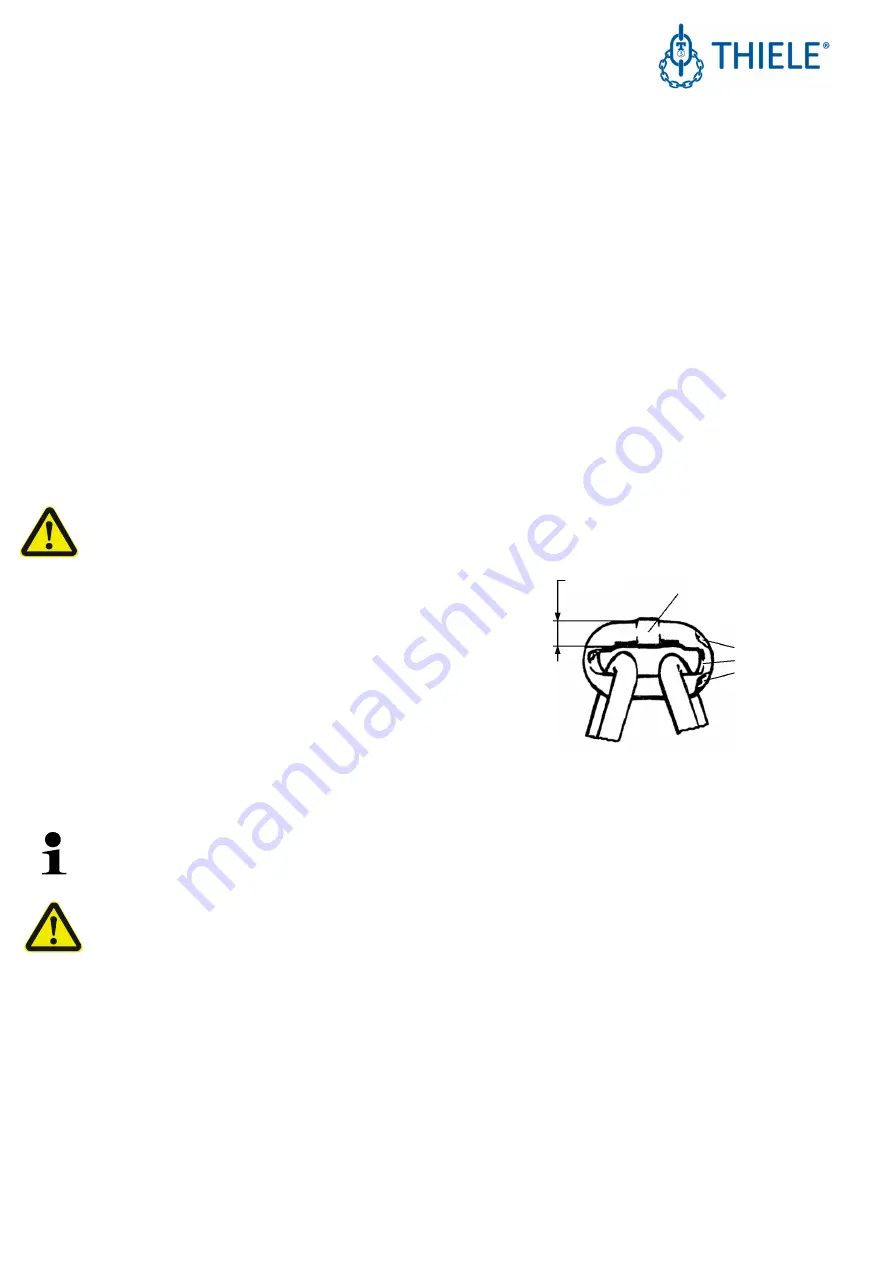

Check

ALL

load chain links in regard to bending, corroding,

locking, stretching, bending and especially to any wear.

The load chain should be taken out of service if the pitch

has increased by more than 3 % or the average wire

diameter reduced by more than 10 %.

If necessary, lubricate the load chain.

A failure of the load chain can occur if the load chain is not

clean and lubricated. If the load chain is dirty and unlubricated, this can lead to premature wear

and subsequent chain failure.

Lubricate the load chain, e.g. with a mineral oil in accordance with DIN 51502 CLP 220 or with a

dry lubricant, e.g. Unimoly C 220 spray in the event of a dusty or dirty environment.

Cleaning (e.g. before testing) must not be carried out by processes that can cause hydrogen

embrittlement (e.g. pickling or dipping in acid solutions).

Diameter

Welding zone

Areas of

heavy wear