MEX VS

Chillers and inverter air / water heat pumps with axial fans

5

The manual of MEX VS units collects all the necessary information for the better use of the equipment under safety conditions for

the operator thus meeting the requirements listed in the 2006/42/CE Equipment Directive and following amendments.

1

PURPOSE AND CONTENT OF THE MANUAL

This manual provides basic information as for the installation, the operation and the maintenance of the MEX VS units. It is

addressed to machine operators and it enables them to use the equipment efficiently, even if they do not have any previous

specific knowledge of it.

WARNING: Although this manual is also destined for the end-user utilizations, some discibed activities are allowed

only for trained technical personnels who should be in possession of Vocational and Technical Training allowing

them to be responsible for carrying out the activity. They should be properly updated with courses approved by the

competent authorities. These activities includ: installation, both ordinary and extraordinary maintenance,

appliance disposal and any other activity required by "qualified staff."

After the end of installation and/or maintenance of the appliance, the qualified operator has a duty to properly

inform the end-user about the use of the appliance and the necessary periodical checks.

The installer is responsible to deliver all necessary documentation (including this manual) to the user and should

ensure him to keep it in a safe place near the appliance where it can be available at any time.

This manual describes the characteristics of the equipment at the time in which it is being put on the market; therefore, it may not

include technological improvements introduced later by the company as part of its constant endeavour to enhance the

performance, ergonomics, safety and functionality of its products.

The company, therefore, is not constrained to update the manuals for previous versions of machines.

It’s recommended that, the user must follow the instructions contained in this booklet, especially those concerning the safety and

routine maintenance.

1.1

CONSERVATION OF THE MANUAL

The manual has to be always kept by the user for future reference. It has to be stored in a safe place, away from dusts and

moisture. It has to be available and accessible to all users who shall consult it when they are in doubt on how to operate the

equipment.

The company reserves the right to modify its products and related manuals without necessarily updating previous versions of the

reference material. It declines also any responsibility for possible inaccuracies in the manual if due to printing or transcription

errors.

The customer shall store any updated copy of the manual or parts of it delivered by the manufacturer as an attachment to this

manual.

The company is available to give any detailed information about this manual and to give information regarding the use and the

maintenance of its own units.

1.2

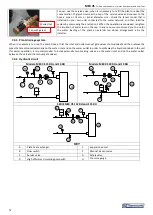

GRAPHIC SYMBOLS

Indicates operations that can be dangerous for people and/or disrupts the correct operation of the equipment.

Indicates prohibited operations.

Indicates important information that the operator has to follow in order to guarantee the correct operation of the

equipment in complete safety.

2

SAFETY LAWS

The MEX VS units have been designed in compliance with the following Directives and Harmonised Norms concerning the safety of

the appliances:

97/23/CE, 2014/35/UE, 2014/30/UE, 2011/65/UE, 2012/19/UE Community Directives

UNI EN 378-1, 378-2, UNI EN 12735-1 Norms

CEI EN 60335-2-40 Norms

CEI EN 55014-1, CEI EN 55014-2, CEI EN 61000-3-2, CEI EN 61000-3-3, CEI EN 62233 Norms

And the following directives and regulations concerning the energy labeling and the eco-friendly products:

Community directive 2009/125/CE and subsequent transpositions

Community directive 2010/30/UE and subsequent transpositions

Regulation UE No 811/2013

Regulation UE No 813/2013

Summary of Contents for MEX VS 112 RH

Page 39: ......