8

9.

PARTS REPLACEMENT

9.01 Heater Replacement

1.

Disconnect power.

2.

Remove the clamps securing the

thermostat bulbs to the floor. Carefully bend

the bulbs to a vertical position.

3.

Remove two screws securing control

panel and carefully lift control panel and

lay it on it's face.

Model 14EG: Then remove three screws

securing the front z-bracket,screws are

located directly above the control panel.

Remove one screw on back wall that

secures the oven floor. Lift bottom floor

straight up and out to remove it.

Model 25 & 45: Remove ten screws that

secure floor and lift out.

4.

Disconnect heater terminals and heater

mounting screws. Carefully lift straight

up and out.

5.

Replace with new heater, reinstall in

reverse order.

9.02 Probe Replacement, Models 25 & 45

1.

Disconnect power.

2.

Remove back panel screws.

3.

Pull probe straight out.

4.

Open control panel by removing top

screws

which secure it and disconnect probe

terminals.

5.

Replace with new probe, reinstall in

reverse order.

9.03 Motor Replacement (Mechanical

Models only)

1.

Disconnect power.

2.

Open control panel by removing top

screws which secure it and disconnect

motor and heater terminals.

3.

Remove screws which secure lower

floor and lift out.

4.

Disconnect/remove heater mounting

screws, remove heater and wires.

5.

Detach blower wheel from motor shaft.

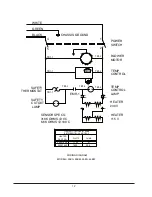

8.04 Heater Resistance Check

WARNING

DISCONNECT OVEN FROM ITS POWER

SOURCE BEFORE PROCEEDING. REFER

TO THE APPROPRIATE WIRING DIAGRAM

AT THE END OF THE MANUAL AND

LOCATE THE ELECTRICAL LEADS FOR

THE HEATER. USE THE VALUES IN THE

HEATER COLD RESISTANCE TABLE TO

FIND THE APPROPRIATE VALUE. BE SURE

TO DISCONNECT AT LEAST ONE HEATER

LEAD FROM THE TERMINAL STRIP

BEFORE TAKING THE RATING WITH YOUR

OHM METER. AGAIN, IT IS IMPERATIVE

THAT THE UNIT BE COMPLETELY

DISCONNECTED FROM ITS ELECTRICAL

POWER SOURCE BEFORE ANY

READINGS ARE TAKEN.

If the heater is open (infinite resistance) it should

be replaced. If the heater reads less than five

ohms it is shorted and should be replaced.

Check the resistance between each lead of the

heater and a base metal point on the oven

chassis. If there is less than infinite resistance

(a million ohms or greater) between the heater

and chassis, the heater is shorted to the ground

and should be replaced. Also, inspect all wires

leading to the heater for signs of shorting or

electrical contact to chassis of oven.