Isotemp

Refrigerators and Refrigerator-Freezers

Installation | 3

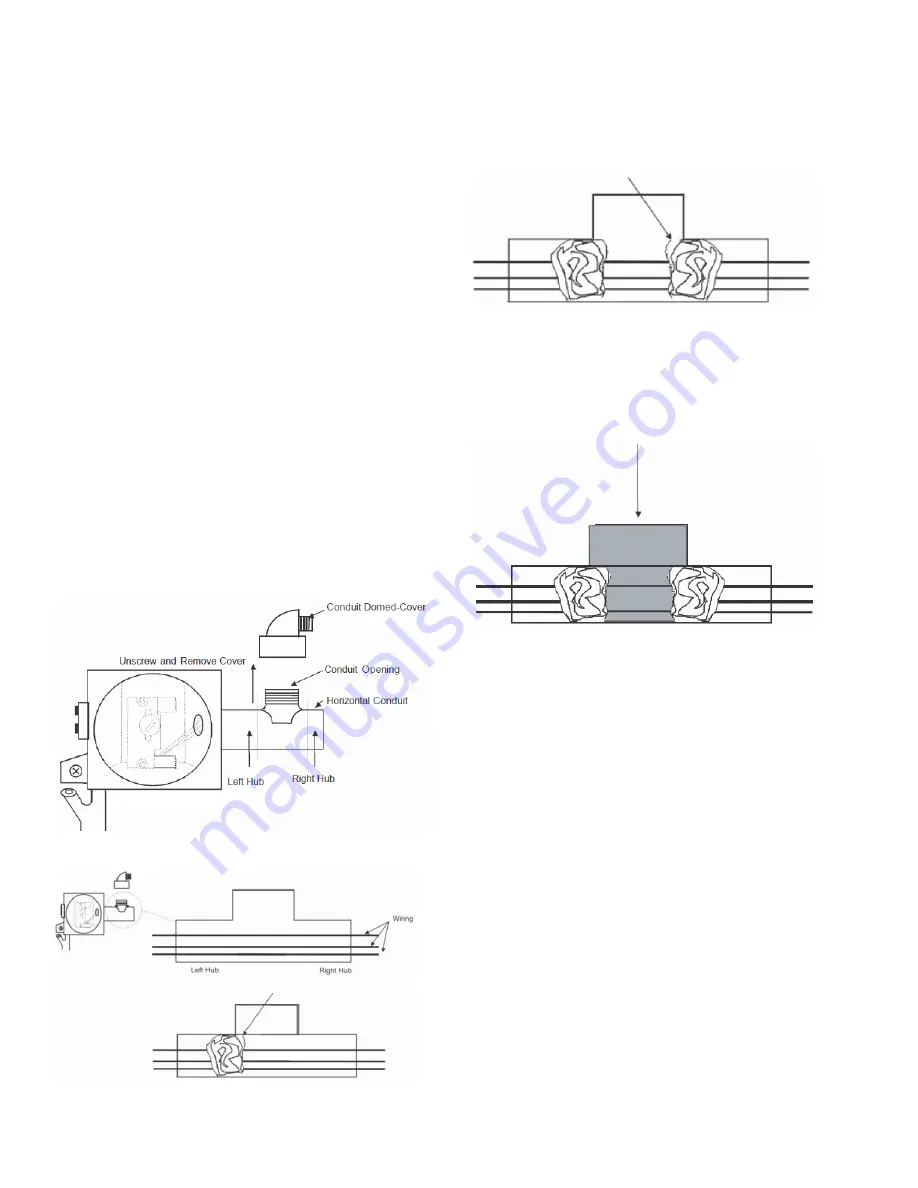

How to Seal Killark

™

Box Conduit with Fiber and

Sealing Compound to Help Protect Against Explosions

(Explosion-Proof Units Only):

The purpose of the procedure that follows is to build fiber

rope dams on the left and right hubs of the horizontal conduit.

The fiber rope damns will surround conduit wiring that is

housed inside the horizontal conduit.

When both the left and right fiber rope dams have been

pressed into place, sealing compound is poured between the

two and forms into an airtight plug.

All of this is done in order to prevent the very real threat of gas

entering the Killark box and a resulting serious explosion. After

the unit wires have been pulled through the horizontal conduit

the following procedure is required:

•

Turn power off at the circuit breaker before

proceeding.

•

Place a small amount of sealing compound granules,

enclosed, into a clean mixing vessel. Add small

amounts of water while stirring until a thick paste is

formed, then carefully continue adding smaller

amounts of water until a thick gravy consistency is

achieved—NOT WATERY. Discard any material that

becomes too stiff to use. Never attempt to restore

workability by stirring in more water.

•

Locate silver Killark box, back/top-center of unit.

•

Unscrew conduit domed-cover.

Figure 1. Sealing the Killark Box

Figure 2. Horizontal Conduit, Cutaway

•

Insert fiber rope material down into horizontal conduit

opening. Pressing down firmly, work the material into the

left hub and—most importantly—being sure the material

COMPLETELY SURROUNDS THE WIRING, from the top

to the bottom, completely blocking this end of the

horizontal conduit.

•

Insert fiber rope material down into horizontal conduit

opening. Pressing down firmly, work the material into the

right hub and—most importantly—being sure the

material COMPLETELY SURROUNDS THE WIRING, from

the top to the bottom, completely blocking this end of the

horizontal conduit.

•

Pour sealing compound down in between the two fiber

rope dams filling the remaining space. Pour slowly, being

careful not to trap air bubbles. Immediately wipe off any

spilled sealing compound.

•

Screw conduit domed-cover back onto conduit opening.

Note:

INITIAL SETUP OF SEALING COMPOUND WILL

OCCUR IN APPROXIMATELY 30 MINUTES HOWEVER, THE

SEALING COMPOUND REQUIRES A

MINIMUM OF 8

HOURS ABOVE 32ºF

TO DEVELOP SUFFICIENT

STRENGTH TO WITHSTAND EXPLOSIONS.