6

Troubleshooting

Diagnostic Tests

112

Accela 600 and 1250 Pump Hardware Manual

Thermo Scientific

Testing the Pump Proportioning Accuracy

This procedure tests the pump’s proportioning accuracy.

To test the pump proportioning accuracy

1. Set up the system as follows:

a. Plumb your system to bypass the autosampler (see

).

b. Connect a 40 bar (~580 psi) restrictor cartridge to the LDA outlet.

c.

Connect the other end of the cartridge to a UV detector with an analytical flow cell

(see

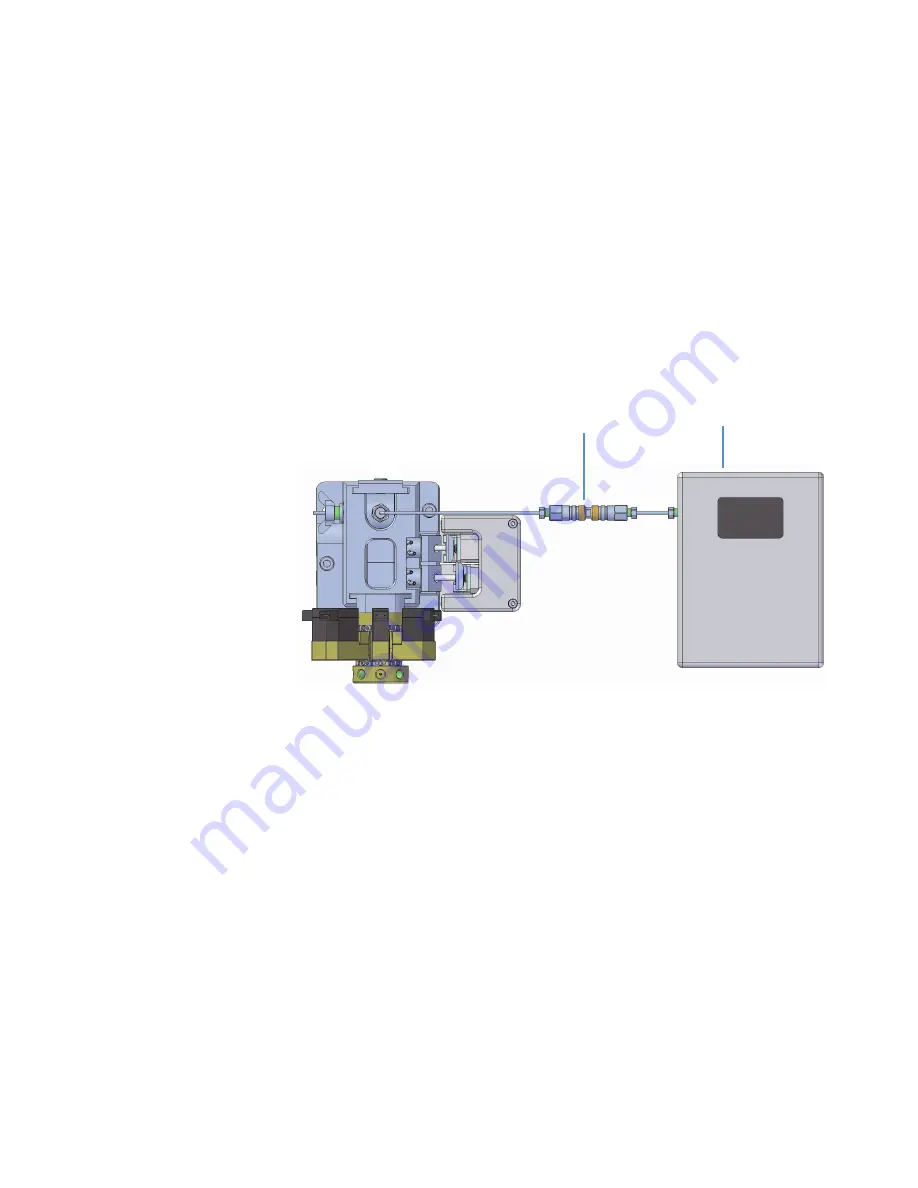

Figure 109.

LDA attached to a flow restrictor

d. Fill a mobile phase reservoir bottle with HPLC-grade water and connect it to inlet

channels A and C.

e.

Fill a mobile phase reservoir bottle with HPLC-grade water spiked with 0.5% acetone

and connect it to inlet channels B and D.

2. Draw solvent through all four channels:

a. Set each channel to 25%.

b. Open the purge valve.

c.

Set the flow rate to 1000 μL/min and start the pump.

d. Wait 2 minutes, and then close the purge valve.

e.

Wait an additional 2 minutes.

3. Pump 100% water and stabilize the baseline at 254 nm as follows:

a. Set channel A to 100%.

b. Set the UV detector to monitor 254 nm.

Flow restrictor

UV detector