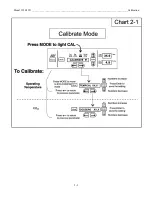

Section 2 - Calibration

2.1 Calibration Mode

After the unit has stabilized, several different systems can

be calibrated. In the calibration mode, the air temperature, CO

2

and RH levels can be calibrated to reference instruments. To

access the calibration mode, press the Mode key until the Cal

indicator lights. Press the right and/or left arrow until the prop-

er parameter appears in the message center. See Chart 2-1 at the

end of this section for more detail.

Calibration frequency is dependent on use, ambient condi-

tions and accuracy required. A good laboratory practice would

require at least an annual calibration check. On new installa-

tions, all parameters should be checked after the stabilization

period.

Prior to calibration, the user should be aware of the follow-

ing system functions. While the unit is in the calibration mode,

all system control functions are stopped so the unit remains sta-

ble. Readout of the system being calibrated will appear on the

message center. If no keys are pressed for approximately five

minutes while in Calibration mode, the system will reset to Run

mode so control functions are reactivated.

Before making any calibration or adjustments to

the unit, it is imperative that all reference instru-

ments be properly calibrated.

a. Calibrating the Temperature

Before calibration, allow the cabinet temperature to stabi-

lize. Place the calibrated instrument in the center of the cham-

ber. The instrument should be in the airflow, not against the

shelf.

Temperature Stabilization Periods

Start-Up

- Allow 12 hours for the temperature in the cabinet to

stabilize before proceeding.

Presently Operating

- Allow at least 2 hours after the display

reaches setpoint for temperature to stabilize before proceeding.

1.

Press the Mode key until Cal indicator lights.

2. Press the right arrow until “TEMPCAL XX.X” appears

in the message center.

3. Press the up/down arrow to match the display to the cal-

ibrated instrument.

4. Press Enter to store calibration.

5. Press the Mode key to return to Run or the right/left

arrow to go to next/previous parameter.

b. Calibrating the CO

2

System

Model 3950 Series incubators have a CO

2

sensor. The incu-

bator atmosphere is not only effected by the quantity of CO

2

present but also by the air temperature and water vapor present

in the incubator atmosphere. In monitoring the effects of CO

2

,

air temperature and absolute humidity must be held constant so

any change is caused by a change in CO

2

concentration.

Changing temperature or changing from elevated humidity

to room ambient humidity levels will require re-calibration of

the CO

2

control.

CO

2

Sensor Stabilization Periods

Start -Up

- The CO

2

sensor has been calibrated at the factory

for 37°C and elevated humidity. Allow the temperature, humidi-

ty and CO

2

levels in the chamber to stabilize at least 12 hours

before checking the CO

2

concentration with an independent

instrument.

Presently Operating

- Make sure the chamber doors are

closed. Allow at least 2 hours after the temperature and CO

2

displays reach their setpoints for chamber atmosphere stabiliza-

tion.

1. Make sure the stabilization periods outlined above are

followed.

2. Sample the chamber atmosphere through the sample port

with an independent instrument. Sample the atmosphere

at least 3 times to ensure accuracy of the instrument.

3. Press the Mode key until the Cal indicator lights.

4. Press the right arrow until “CO2 CAL XX.X” is dis-

played in the message center.

5. Press the up /down arrows to change the display to

match the independent instrument.

6. Press Enter to store the calibration.

7. Press the Mode key to return to Run or the right or left

arrows to go to the next/ previous parameter.

Model 3950/3951 _____________________________________________________________________________Calibration

2 - 1