S

Series

Service Set-Up Records

Initial Set Up

1 2 3 4

1. Date

2. Model Number

3. Firing Rate

4. Pump Pressure Set 140 PSI

5. CO

6. "O" Smoke

7. Gross Stack˚

8. Draft Over Fire

9. Replaced Filter Yes/No

10. Replaced Nozzle Yes/No

11. Clean Pump Filter Yes/No

12. Inspect Coil Gasket

13. Check for leaks @ plugs/fittings

14. *Brush Clean Flue Tub Passages

15. Vacuum Chamber/Flue Tubes

16. Clean Blower Wheel

17. Check/Set Electrodes

*Soft fiber chamber...Exercise care to avoid damage.

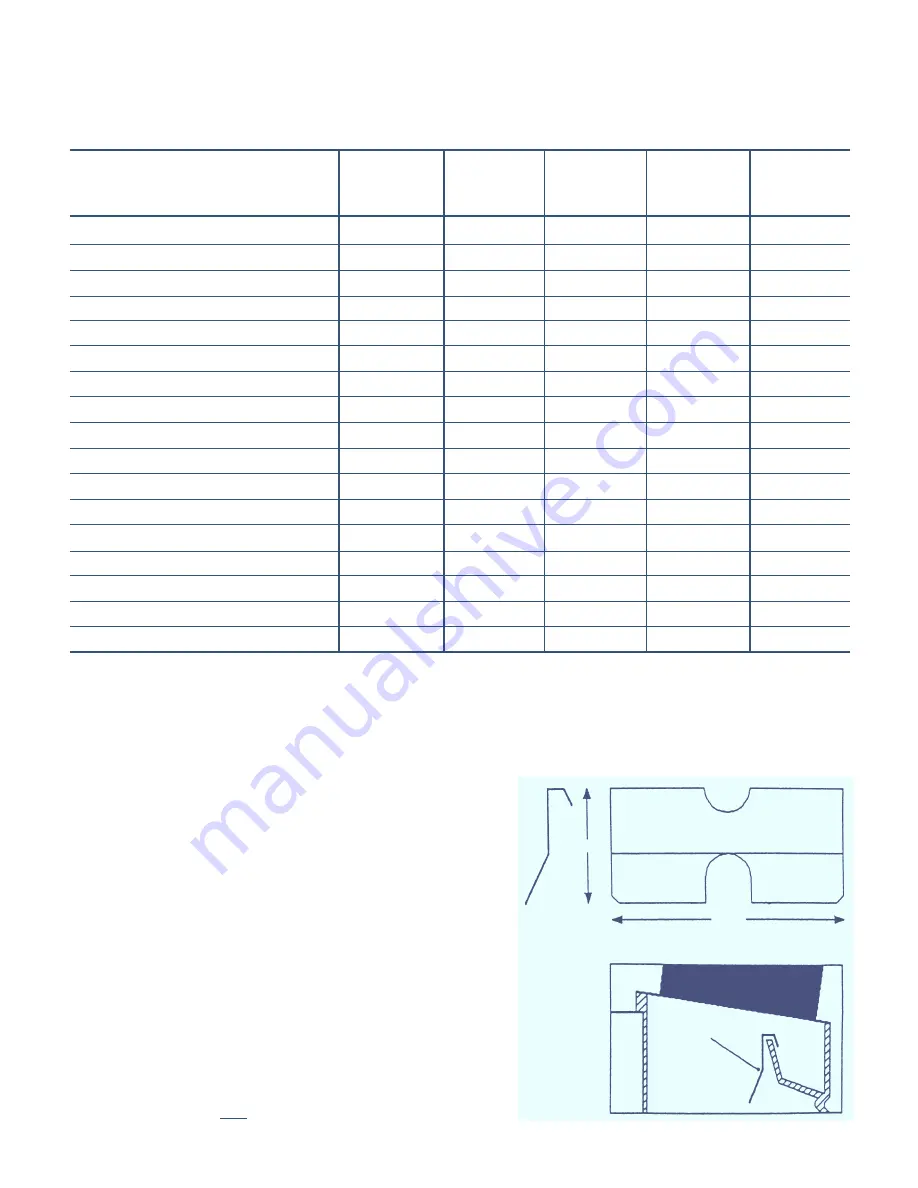

EXPLANATION OF LOW FIRING RATE BAFFLE

The Beckett low firing rate baffle is a small metal plate. It is

installed over the back of the blower wheel scroll, which is

visible when the transformer is swung back.

The low firing rate baffle is used to partially restrict the flow

of combustion air to the combustion head. When the baffle is

placed in the stream of air going from the blower wheel to the

head, it increases the load on the blower wheel. This reduces

the CFM and increases the operating pressure.

At the lower firing rates the combustion head has an easier

time controlling the reduced air supply. The result is better

starts and running characteristics. Flame stability at start-up

is improved due to higher blower operating pressure which

tends to dampen flame pulsations. It also means less sensi-

tive air shutter adjustments.

Another advantage is that the inlet air controls must now be

opened more to overcome the added resistance of the baffle.

This means that the openings are less prone to restriction

due to buildup of dust, lint or pet hair.

The baffle is used only on the model S-85.

1 3/4"

3 3/4"

Low Firing Rate Baffle

figure 1

figure 2

MET-3937

8/14-500