13

ENGLISH

INSTALLATION

INSTALLATION

FILLING AND EMPTYING

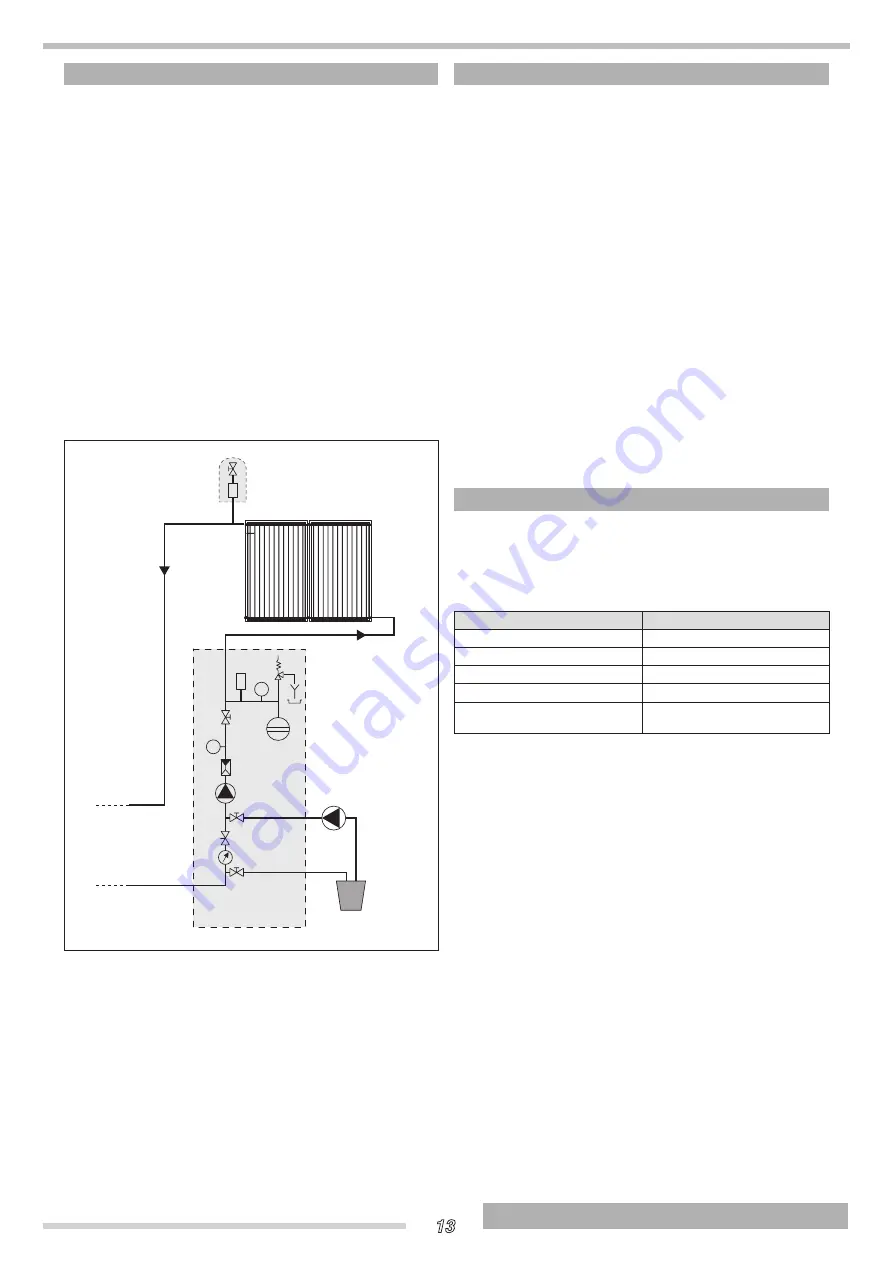

Before system commissioning it is necessary to wash and fill it.

Solar collectors are exposed to the risk of frost during winter,

as they are installed outdoor. Moreover, they can reach high

temperatures in stagnation conditions, consider these things

when choosing the heat transfer fluid.

b

If copper piping has been used and joints have been hot

brazed, flush out the system to remove any brazing res-

idues. Seal test the system after you have flushed it out.

Fill the solar collector with glycol/water mix immediately

after flushing it out, because flushing water may remain

trapped in the circuit (with a consequent risk of freezing).

b

For system washing, filling and emptying, follow the in-

structions contained in the manual of the matched solar

station.

b

Filling, emptying and venting must be carried out with

collectors at ambient temperature and protected from

solar radiation.

A

7

°C

Manual

bleed valve

(accessory)

Anti-freez mix

Heat exchanger

of solar

Solar collector

Heat

transfer fluid

filling pump

Water control system

R

M

M

T

DEVICE CLEANING AND MAINTENANCE

b

The following operations must be exclusively performed

by Technical Assistance Centre

It is recommended to clean the glass once a year, as the de-

posit of dust and leaves reduces system efficiency.

The collector must be cleaned with water or water and soap.

Dry the collector at the end of cleaning operations.

a

Do not use abrasive products, petrol or triethylene.

The heat transfer fluid must be checked every 2 years to ver-

ify the effectiveness of water and glycol mix, including its pH

value.

- Check the antifreeze with the suitable instrument - re-

fractometer or hydrometer- (nominal value approx.

-30°C): if the limit value of -26°C is exceeded, replace

or top-up the antifreeze.

- Use litmus paper to check the pH (nominal value ap-

prox. 7.5). If the measured value is below 7, change the

heat transfer liquid.

Check the integrity of insulation and expansion joints.

RECYCLING AND DISPOSAL

The device is primarily composed of:

At the end of the device's useful life, these components must

be separated and disposed of according to current regulations

in the country of installation.

Material

Component

Glass

Cover

Brass - Copper - Aluminium

Absorber

Rock wool

Insulation

Aluminium - Steel

External frame

Silicone - PA66

Sealing elements of connec-

tions