1.5mm

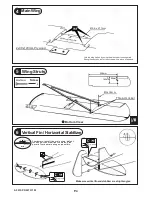

Canopy

13

PWA2.3x8mm

Screw

d1.5x6.5mm

Silicon Grommet

4

4

d1.5x6.5mm

Silicon Grommet

PWA2.3x8mm

Securely glue the windows to the fuselage.

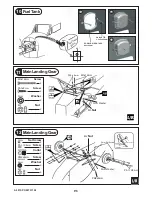

Cowling

14

PWA2.6x12mm

Screw

d1.5x6.5mm

Silicon Grommet

4

4

PWA2.6x12mm

d1.5x6.5mm

Silicon Grommet

Trim the cowling for the

engine head to project.

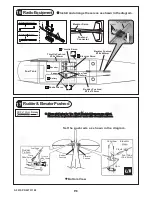

Servo Set

15

1

1

3x3mm

Set Screw

Linkage Connector

M2

Nut

2mm

Washer

1

2

Please refer to the attached sheet for linkage connector installation.

Th

ro

ttl

e P

us

hw

ire

3mm

Throttle Servo.

2

m m

2mm

Washer

M2

Nut

2mm

Washer

P.7

A001SPO26731108

PWA2.6x12mm

Silicon Grommet

d1

.

5xD6

.

5mm

Cowling

Fuselage

First insert the groment to the cowling then apply screw

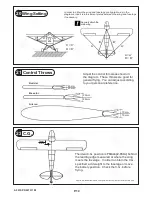

Please refer to the attached sheet for usage of the

transparent 3D template

Summary of Contents for PIPER J-3 CUB 48S

Page 16: ...A001SPO26731108 ...